18 Different types of circuit breakers – their construction, operation and applications

18 Different types of circuit breakers – their construction, operation and applications

We cannot imagine our life without electricity especially in this modern age. Almost everything is powered by electricity. Whether it is from the mains or from the battery, we must keep it under control. Any electrical failure can cause damage or even death. Therefore, we use multiple protection devices such as circuit breakers to avoid such risks.

What is a circuit breaker

What is a circuit breaker

A circuit breaker is a mechanical switch that automatically operates to protect a circuit from damage caused by fault current. It automatically breaks the circuit upon sensing a significant drawdown of the current flow due to an overload or short circuit. It can also manually break the circuit for maintenance or troubleshooting. It can safely close and open the circuit to protect it from damage

The circuit breaker cuts off the supply to the circuit when the current exceeds its rated current. The current may exceed for many reasons such as overloads, short circuit, voltage spikes, etc. Overloading occurs when the load draws a current that is much more than the rated current. A short circuit occurs when two exposed wires come into contact with each other by any means.

What should the circuit breaker do?

The main objective of a circuit breaker is to open the circuit safely

- It must momentarily withstand faulty current

- You must break the circuit safely

- The arc should extinguish quickly.

- Its limbs must bear the stress after breaking.

- It should prevent the arc from being hit again.

The circuit breaker temporarily resists the fault current and allows other circuit breakers to resolve the fault. The CB is designed to withstand a certain range of current faults without damaging its terminals.

Once it detects fault current, it cuts off and interrupts the current flow. It breaks a circuit by using some type of stored mechanical energy like a spring or a blast of compressed air to separate the contacts. It can also use the fault current to open the contacts using thermal expansion or electromagnetic field using a solenoid.

The next step that comes after the contacts are separated is the arc extinction. The arc is generated between the contacts due to the high voltage between them. It can damage the CB contacts or terminals due to excessive heat generated by the current surge.

Media used for arc extinction

The electric arc tries to make up the circuit, so current still flows in it. It must be extinguished and different types of circuit breakers use different insulation media or dielectric arc extinction such as.

- air

- broom

- insulating oil

- Insulating gas such as SF6 (sulfur hexafluoride)

Other than the method used in arc quenching, various arc extinction techniques are used to remove the arc quickly and safely.

Methods used for arc extinction

- Arc quenching : The arc heats up the air molecule that ionizes and reduces air resistance. Arc cooling will recombine the ionized particles in their normal state and increase the dielectric strength of the air molecule. As the resistance of the medium increases, the voltage required to sustain the arc also increases and the current begins to decrease causing the arc to cool.

- Air Blowing : This method is used in air blast circuit breakers, where the arc is quenched using a blast of compressed air. The ionized air molecules are replaced by non-ionized air molecules with a higher dielectric strength. It increases the resistance and thus reduces the current which leads to arc extinction.

- Increasing the length of the arc : The length of the arc is directly proportional to its effort. Increasing the arc length by pulling the contacts apart increases the effort required to maintain it. So it will turn off.

- Reducing the arc cross-section: Another technique is to reduce the arc cross-section by reducing the contact sizes. Therefore, the voltage required for the arc increases and extinguishes it.

- Arc Deflection: In this technique, a magnetic field is created to deflect the arc. The arc blows in a part of the circuit breaker called the arc duct where it is cooled and extinguished.

- Arc Splitting or Dividing: In this technique, the arc is divided into multiple arcs by establishing multiple contacts between them. The bow is divided into several series of small bows, which increase its length and resistance. Therefore, reduce the arc current and finally extinguish it.

- Zero Current Cooling: This is the most common method used in AC circuit breakers. There are inherently several zero currents in the AC waveform. The circuit is open at exactly zero current. So that the current does not rise to generate the arc.

- Using a Capacitor Charged in Parallel : This technique is used in a DC circuit breaker. DC has no natural zero currents. Therefore, a capacitor charged with an inductor in parallel is used to introduce an artificial zero current in the line to extinguish the arc.

Basically, it is necessary to install a circuit breaker on every line to protect it from any kind of dangers or disasters. The circuit breakers are manufactured by keeping in mind various features such as;

- intended voltage applications

- Alternating or direct current

- installation site

- Design characteristics

- The method and means used for current interruption (Arc Extinction)

There are different types of circuit breakers that are distinguished based on different characteristics. Electricity breakers are mainly classified into two types;

- AC circuit breakers

- DC circuit breakers

AC circuit breakers

Alternating current refers to an alternating current whose voltage and current fluctuate along zero value many times per second. The energy at this zero point is empty which can be used to break the circuit without generating an arc.

The circuit breakers used in alternating current are completely different from those in direct current. The zero junctions inherent in AC current provide multiple opportunities per second for the arc to extinguish itself.

The arc strength is directly proportional to the voltage level. Therefore, low voltage arcs can be easily extinguished, but higher voltage arc requires a more sophisticated approach to extinguish. Therefore, CB’s are rated based on their voltage level.

High voltage AC circuit breakers

The definition of high voltage depends on the context. IEC considers high voltages as voltages greater than 1000 volts. This voltage tends to generate an arc that cannot be easily concealed. The circuit breakers used for making and breaking contact at such voltages are called HV circuit breakers.

Arc extinction can be done using various methods at such high voltages. The high-voltage circuit breaker may or may not use oil for arc extinction; Therefore, they are classified into two types:

- Oil circuit breaker

- Electricity breakers without oil

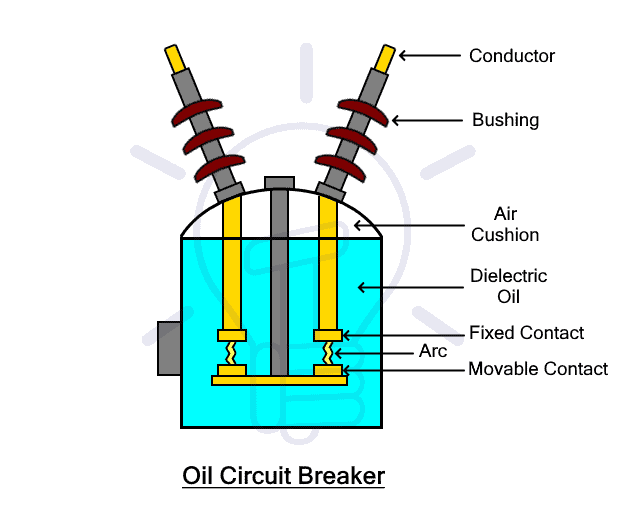

The type of circuit breaker that uses oil as an insulating medium or insulator to quench the arc is called an oil circuit breaker. It is considered one of the oldest types of high voltage circuit breakers and mainly uses transformer oil . The oil used in such breakers has very good insulating properties much better than air. The CB contacts are immersed in oil which is used to quench the arc once the contacts are separated. The heat generated by the arc is dissipated into the oil.

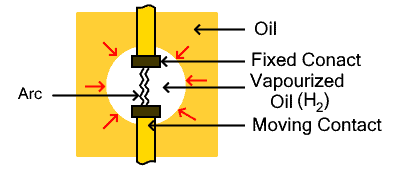

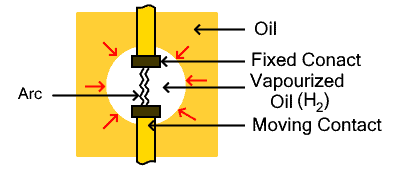

When the CB breaks its current-carrying contacts within the oil, the distance between the contacts begins to increase. Initially, there is a very small distance between the contacts but there is also a very high voltage gradient. As a result, the oil between the contacts begins to ionize and create an arc between the contacts.

The arc generates a lot of heat and vaporizes the oil around it which mostly decomposes into hydrogen gas. Hydrogen gas bubbles rapidly form around the contact, approximately ten times the volume of the oil. This oil surrounding the gas bubbles puts a lot of pressure on it, which leads to increased ionization of the medium. The ionization of the medium increases its dielectric strength which will quench the arc at the current zero junction.

In addition, the cooling effect of the oil and gas bubbles also helps in cooling the arc.

Based on the amount of oil used in OCB (Oil Circuit Breaker), it is classified into two types

- Bulk Oil Circuit Breaker (BOCB)

- Minimum oil circuit breaker (MOCB)

Bulk Oil Circuit Breaker (BOCB)

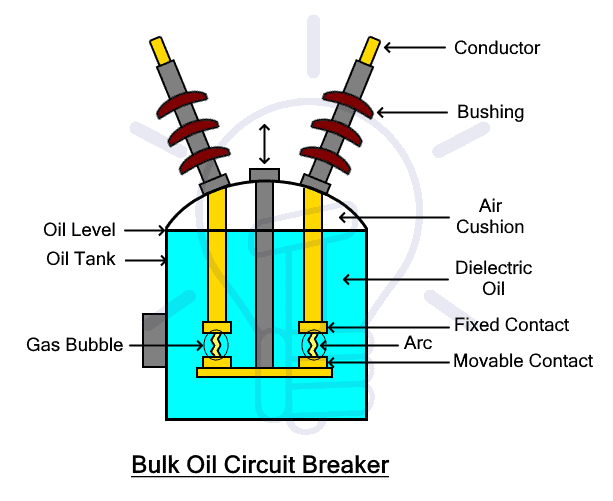

This type of oil circuit breaker uses insulating oil to quench the arc as well as isolate the live contacts from the grounded parts of the CB. CB uses this oil in large quantities.

BOCB has an iron tank that holds the insulating oil inside. The contact points (fixed and movable) are immersed in the oil. When the contact points are broken, the arc generates heat and produces gas. The compressed gas displaces the oil inside the tank as the air above the tank is used as a cushion. Therefore, the tank should not be completely filled with oil. Also, the tank must be strong enough to absorb the pressure created by the gas. There is also a gas vent to release gas safely outside.

Arc quenching is done using compressed gas generated by the heat of the arc. As the contacts move, the distance between the contacts also increases. It also increases arc resistance. Also, the quenching effect of the gas also plays its role in quenching the arc once the current passes through the zero point.

BOCB is further divided into two types based on the division of brackets to quickly quench them.

Single break bulk oil circuit breaker

In a single break BOCB, there is one static contact and one movable contact. When a current fault occurs, the moving contact drives back an arc generator which is quenched by the compressed gas within the oil. As the name implies, there is only one separator between the contacts.

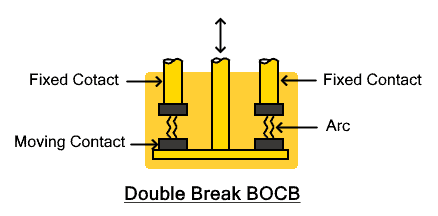

Double bulk oil circuit breaker

In a BOCB double splitter, there are two static contacts and one movable contact. Fixed contacts are fixed to the tank at both ends connected to live conductors while moving contact can move up and down using an insulating rod.

Under normal circumstances, the moving contact is pushed up to make contact at both ends with the fixed contacts. In the event of a fault, the moving contacts are pulled down to break the contacts and generate arcs at both ends. In this way, the arc is divided into two parts which have lower strength which can be easily cooled and quenched inside the oil.

- The oil used for arc quenching has a very high dielectric strength

- Oil isolates live contacts from grounded parts

- Oil produces hydrogen gas by heat from the arc which is useful for arc cooling.

- Oil pressure compresses the gas to remove ions from the medium.

- The gas also helps cool the medium.

cons

- Oil is flammable and poses a fire hazard.

- Contacts can be damaged with the arc.

- The carbonization of the oil from the contacts reduces their dielectric strength.

- The oil and contact points should be checked and maintained regularly.

- Using an enormous amount of oil increases its cost

- Its large oil-filled tanks are heavy and take up a lot of space.

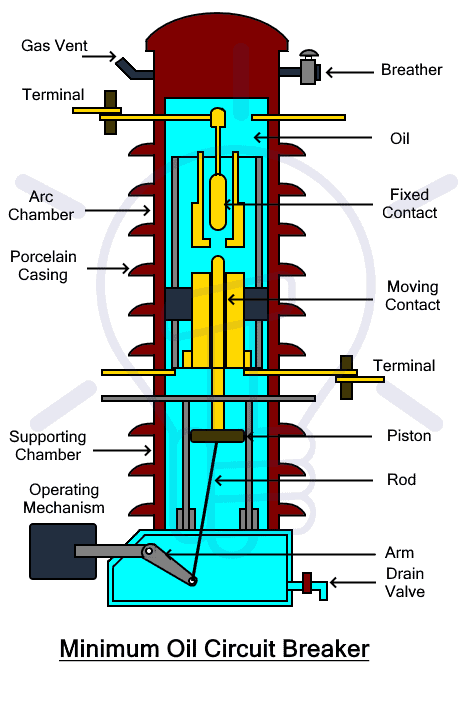

Minimum oil circuit breaker (MOCB)

As we know, the oil circuit breaker uses a large amount of oil to quench the arc which may pose a threat to the fire hazard. To reduce these risks, MOCB uses much less oil than BOCB. Oil is used only for arc cooling and not for isolating live parts from grounded parts.

MOCB has two chambers: the arch chamber and the supporting chamber. The bow chamber is made of porcelain covered in baked paper. Filled with insulating oil. This chamber is used for arc suppression. Contains fixed and mobile connections.

The supporting chamber is made of porcelain superimposed over a metal chamber. This chamber is used to isolate the bow chamber as well as to support the bow chamber by attaching it above it. This chamber is also filled with oil used only for insulation.

The movable connection moves up and down with the help of an arm fixed in the supporting chamber. The movable contact contains a fixed piston which is used to push the oil up which helps to quench the arc.

Under normal circumstances, the lower movable contact makes contact with the upper fixed contact. If a fault occurs, the arm pulls the movable contact down and an arc is created. This arc is extinguished by the compressed gas contained in the oil around it by forcing the oil out of the support chamber with the help of a piston. As the contact moves down, a vent hole becomes available for hydrogen gas to escape.

In terms of venting, MOCB is divided into two types.

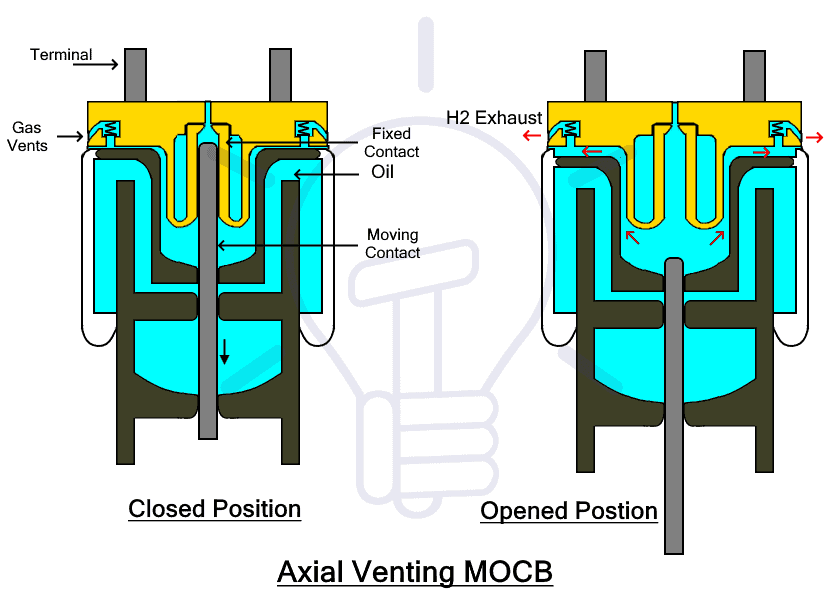

Axial Ventilation MOCB: In axial ventilating MOCB, the arc chamber openings are designed in such a way that when the moving contacts slide down to break the circuit. A slot allows cold oil to move from the bottom slot sweeping the arc in the axial direction through the top slot.

Axial venting generates very high pressure and therefore has very high deionization capabilities and thus a high dielectric strength of the oil. It is used for low current at high voltages.

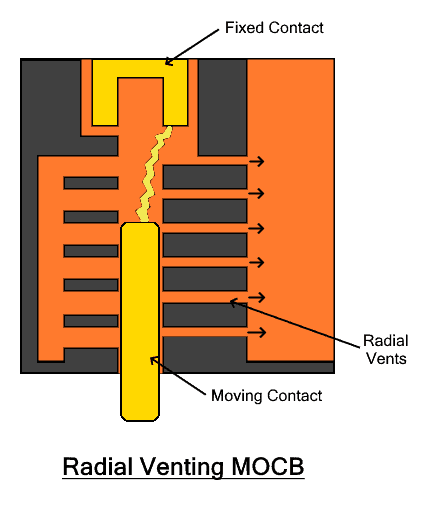

MOCB Radial Venting: During MOCB radial venting, the vents are designed radially along the arc chamber. Therefore, the arc is swept radially through multiple vents.

The radial orifice has a low pressure and therefore the oil has a low dielectric strength. Therefore, MOCB is used for radial venting of high current at low voltages.

A combination of axial and diagonal ventilation is used within a single MOCB to efficiently break low and high voltages.

Advantages

- It requires less oil.

- Less oil means less risk of fire.

- It has a light weight.

- It has a small size and takes up little space

- It is cheaper than BOCB.

- It is easy to maintain and the oil can be easily replaced.

- Best for installing in places that are not used frequently.

cons

- Less oil is more affected by the amount of carbonization of the contacts.

- Oil quickly loses its insulating power.

- It requires more frequent maintenance.

Oil thrust circuit breaker

In MOCBs discussed above, stress is developed by the arc which depends on the amount of arc current. Therefore, it is not suitable for low current electric arc quenching. Oil thrust CB is another type of MOCB where the necessary pressure is developed by external mechanical means using a piston attached to the moving contact. The pressure developed in this way is independent of the fault current. It uses much less oil than a conventional MOCB and can extinguish the arc independent of current and voltage.

This type of high voltage circuit breaker does not use oil as the arc cooling medium. There are different types of arc quenching media that can be used in place of oil. Below are the type of oil free CBs using different arc quenching medium;

- Air breakers

- Air breakers

- SF6 circuit breakers

- CO circuit breaker

- Circuit breaker

Air Circuit Breaker (ACB)

Air circuit breaker or ACB is a kind of oil-free high voltage electric circuit breaker which uses air as the arc extinguishing medium. It is used for short circuit and overcurrent protection up to 15 kV and 800 to 10 kA. It is preferred over an oil circuit breaker because there is no flammable oil and fire hazard.

As we know, the aim of a circuit breaker is to safely extinguish the arc and prevent the arc from being re-struck. In order to extinguish the arc we have to increase the arc voltage (minimum voltage required to sustain the arc). ACB uses air as a medium to extinguish the arc. Unlike other media, air can be used in different ways to extinguish the arc using various methods such as arc quenching, arc length increasing, arc splitting and air blasting, etc.

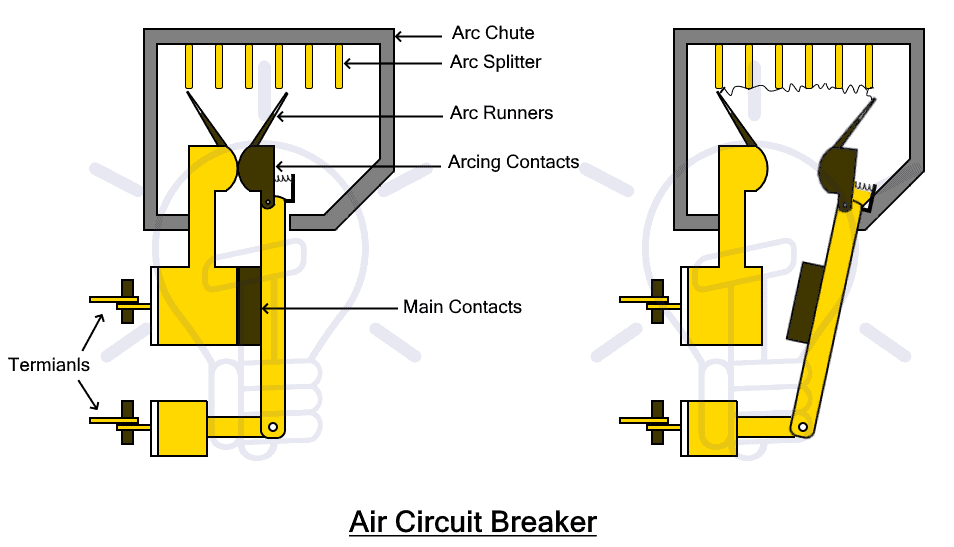

In an ACB, there are two pairs of contacts, i.e. main contacts (made of copper) and arc contacts (made of carbon). Under normal circumstances, the main contacts are used for normal current supply. Under fault current, the main contacts open while the arc contacts remain closed.

Once the main contacts open, current will flow through the arc contacts. At this point, there is no arc and the main contacts are secure. An arc is generated once the arc contact is opened. The arc sweeps upward causing cooling and increasing arc length. Thus the arc is quenched at zero current.

ACB is further divided into the following types.

- Ordinary air circuit breaker

- chute arc breakers

- Magnetic circuit breakers

- Air breakers

Ordinary air circuit breaker

Ordinary air circuit breaker is the simplest air circuit breaker. Also known as cross circuit breaker. It contains a chamber surrounding the main contacts. This room is called the Bow Waterfall. It is used to extinguish the arc which is made of refractory material. It contains several small compartments made of separating sheet metal.

The metal separation within the arc raceway acts as an arc separator and divides the arc into small arcs that increase the effort required to maintain the arc. The air also sweeps up the arch, cooling it. Thus the arc is quenched at zero current. It is used for low voltage applications.

Air lubricant circuit breakers

The air separation circuit breaker has two types of contacts, i.e. main contacts and arc contacts. The main contacts are made of silver plated copper to reduce their resistance. Bending joints are made of a copper alloy that has a high heat resistance to absorb the damage caused by arcing.

Under normal operation, both numbers are closed. The main contacts conduct current due to their low resistance. When the main contacts open, the current is diverted through the curved contacts. Next, the arc contacts where the arc is generated and quenched are opened. Arc contacts can be easily replaced in case of wear and tear.

Magnetic circuit breakers

This type of air breaker contains a blasting coil that generates a magnetic field. This magnetic field deflects the arc into the arc stream to lengthen its length as well as cool it. The arc is extinguished inside the cutter. The magnetic field does not directly quench the arc but only deflects it which is subsequently quenched by air. Provides arc control to maximize its effort. Electric circuit breakers are used up to 11 kV.

Air breakers

Air Blast Circuit Breaker, or ABCB, uses a blast of compressed air to interrupt the arc. The air is stored and compressed in a tank. This air is shot through a nozzle at a very high speed to extinguish the arc. They have a high voltage capacity of up to 450KV. They are used for 220 kV lines in switch yards.

Air explosion circuit breaker is divided into four types

- Axial air circuit breaker

- Axial blast with sliding contact moving ACB

- Radial blast air circuit breaker

- Crossed air circuit breakers

Axial blast ACB

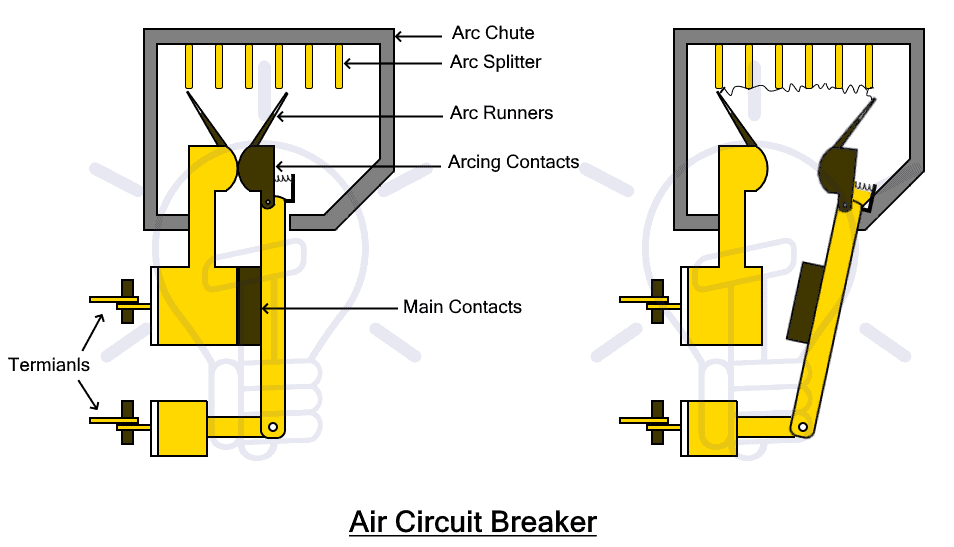

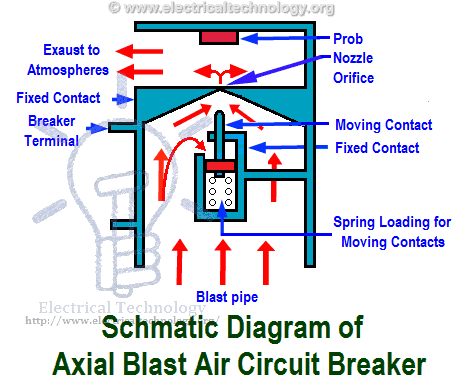

In an ACB axial blast, the airflow flows axially in the same direction as the arc. The air lengthens the arc and cools the arc at the same time and also increases the dielectric strength of the medium to prevent the arc from striking again.

The movable contact under the force of the spring is in a closed position with the fixed contact. The fixed contact has a nozzle hole blocked by the end of the moving contact. Compressed air is stored in the tank below. When a fault occurs, the compressed air is released which forces the spring to retract the movable contact, thus opening the nozzle hole in the fixed contact. The arc strikes between the contact points are lengthened and cooled by the airflow through the opening. All this happens simultaneously and the arc turns off.

Axial blast ACB with sliding movable contact

This type of breaker is a modified form of the ACB axial blast. It has a spring-mounted, horizontally moving contact with a piston. The fixed contact has the same type of orifice opening which is blocked by this moving contact. It has the same arc quenching process as discussed in the previous ACB.

Radial Blast ACB

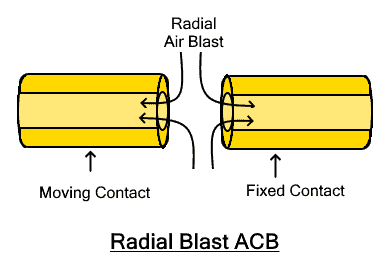

In ACB radial blast, the contacts are hollow like a tube, i.e. there is free space inside the moving contact as well as the fixed contact. The free space of the compressed air flow is used for arc cooling. Air flows radially inside the contact points along the arc so it is called radial blast (ACB).

Under fault conditions, an arc is formed between the contacts when they are separated. Radial air cools the arc and increases the insulation strength between the contacts. At zero current, the arc is extinguished.

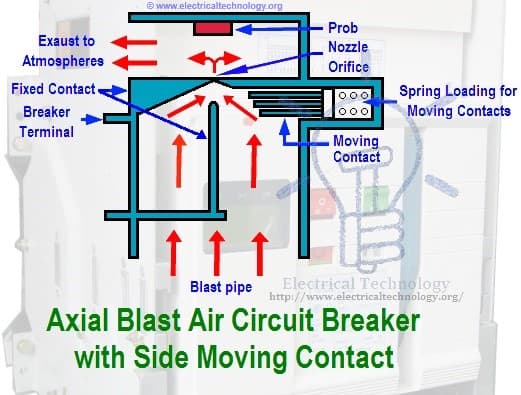

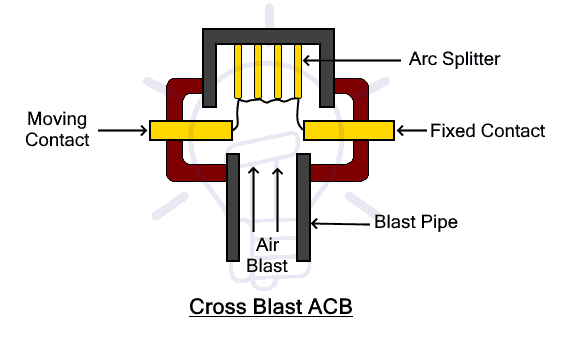

Cross Blast ACB

In ACB cross blasting, the air blast is directed at right angles to the arc. Blast air is used to deflect and lengthen the arc into the arc chamber where the arc splitters split the arc and lengthen the arc to quench it. There is an exhaust in the bow chamber for air flow.

The air tank is installed in the vertical direction of movement of the contacts. In the fault condition, the contacts are opened and the arc is created. At the same time, an arc-sweeping air blast is released in the arc chamber. Arc dividers produce an arc which is eventually quenched at zero current. The air blast also increases the dielectric strength of the medium between the contacts to prevent the arc from rebounding.

Advantages of ACB

- ACB does not have any fire hazards, unlike oil breakers.

- ACB has a very high speed, that is, the arc cooling is very fast.

- The arc cooling speed is the same for all current values.

- It is of small size due to the small area required for the air blast to cool and quench the arc.

- It is used for frequency playback where circuit breaking and making are performed as often as in switch yards.

- It is very reliable and consistent because the short arcing time can not quickly wear the contact.

- Less maintenance is required due to less contact lens wear.

- ACB is somewhat cheaper as air is used as the arc cooling medium.

ACB defects

- The air compressor needs to be serviced to get the correct pressure all the time.

- The air compressor takes up a lot of space.

- Intersecting air ducts may cause air pressure leakage.

- There is a chance of a high rate of surge in re-hitting voltage and cutting current.

- The air makes noise.

- Air compared to other insulating gases has lower extinguishing properties.

Sulfur hexafluoride (SF6) circuit breaker

Sulfur hexafluoride or soon known as SF6 is an insulating, non-flammable gas with a very high electrical potential. It has a high tendency to absorb electrons.

When an arc is struck between the contacts, the medium is ionized due to the free electrons. SF6 absorbs free electrons and forms negative ions that are much heavier than the free electrons. Due to its heavy weight, it is immobile and reduces the movement of cargo. This enhances the dielectric strength of the medium where the arc is quenched. SF6 has much higher insulating capabilities and arc quenching than air about 100 times better.

There are three types of SF6 circuit breakers

- SF6 circuit breaker is non-sprayer type

- SF6 single-pressure circuit breakers

- SF6 double-pressure circuit breakers

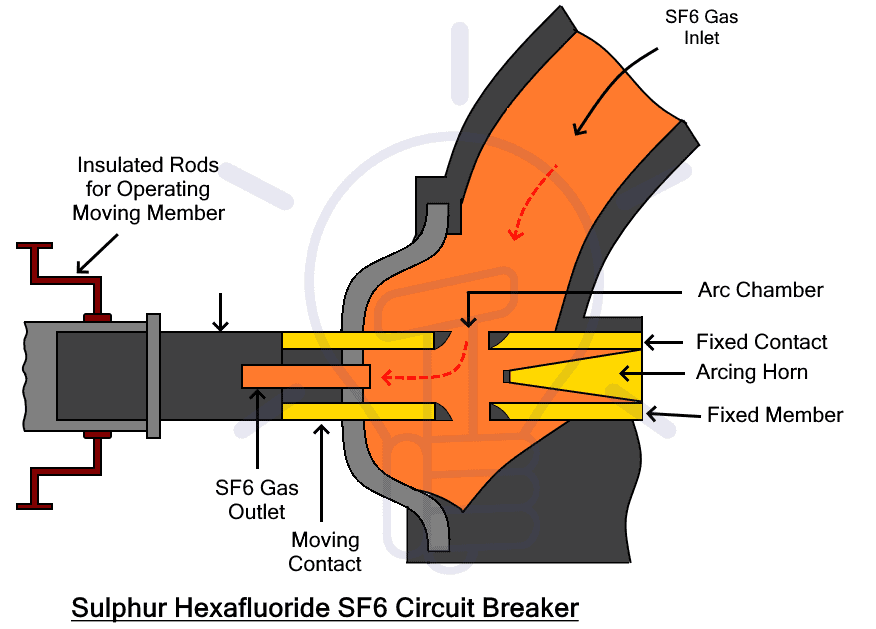

Non-sprayer type

In a non-atomizer SF6 CB, compressed SF6 gas is stored in the gas chamber. while the arc is cooled inside a cutting unit. This unit has movable and static contacts and is mainly hollow cylinders. The fixed connection has arc horns while the movable connection has openings for the flow of compressed gas.

In the event of a fault, the moving contact is moved away from the fixed contact. Its movement is synchronized with the valve of the gas chamber. Once the contacts are open, the valve is opened and pressurized SF6 is inserted into the arc chamber. SF6 dampens the arc and flows through the hollow moving contact. This gas is then recaptured and pumped back into the gas chamber for reuse.

SF6 non-atomizer circuit breakers were used when they were first invented. Nowadays the easiest and simplest SF6 cutters using an atomizer cylinder are used.

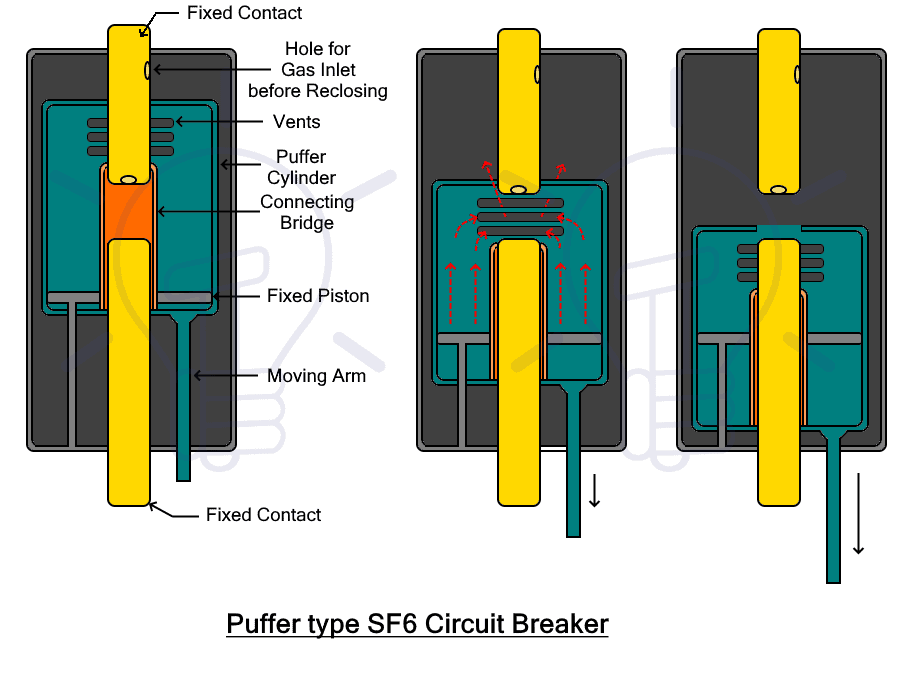

SF6 single-pressure circuit breakers

This type of SF6 CB contains the atomizer cylinder. The atomizer cylinder is a hollow cylinder that acts as a bridge between two fixed contacts. The roller can slide up and down axially along the contacts. There is a fixed piston inside the atomizer cylinder as shown in the figure. By moving the cylinder, its inner volume can be varied.

At this point, the fixed top contact blocks the holes in the atomizer cylinder, so SF6 cannot flow out. By moving the roller downwards, the nozzles are opened and the contacts are opened. An arc is generated as well as SF6 begins to flow through the hollow contacts. This compact SF6 tells the arc.

The same process is done in the opposite direction to close the circuit. By moving the cylinder up, its volume increases and a low pressure is generated. As a result, SF6 flows from the periphery into the cylinder through the contacts and vents.

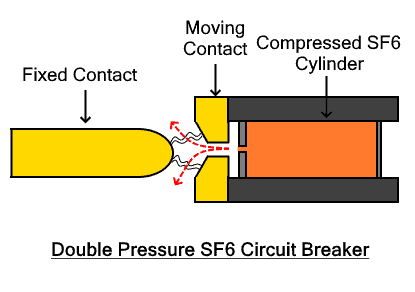

SF6 double-pressure circuit breakers

These types of SF6 circuit breakers are obsolete. In such breakers, the gas is compressed and stored in a chamber which is released when the contacts are opened to quench the arc. It has the same process as CB compressed air except the gas is re-compressed and stored in a gas chamber.

The SF6 cylinder is inside the moving contact which is blocked by the fixed contact in a closed position. When the contacts separate, an arc is produced. At the same time, the high pressure gas rushes from the cylinder to the low pressure area. An explosion of sulfur hexafluoride quenches the arc as discussed earlier. The gas is filtered, compressed and returned to the cylinder for reuse. It is outdated due to the complex gas system required to maintain gas. It also includes a heater in case the gas is liquefied due to low temperature.

Advantages of SF6 circuit breaker

- Sulfur hexafluoride has super arc quenching that is 100 times more efficient than air.

- The arcing time of SF6 circuit breaker is very short.

- The dielectric strength of SF6 gas is two to three times higher than that of air. It also increases with increasing pressure.

- Due to the high dielectric strength, the required contact separation is small to prevent arc re-installation.

- High dielectric strength results in high current interruption potential.

- SF6 CB has a compact design. Thus requiring little space and installation cost.

- SF6 gas can handle all kinds of diversion phenomena.

- The SF6 CB has a closed circuit gas system with no leakage. So, it is best for any installation in any kind of (extreme) environment.

- Carbon molecules do not form with bending, so the dielectric strength does not decrease.

- It does not require an expensive and bulky air compressor system except for the outdated dual compression type.

- Operation of the SF6 CB is silent.

- SF6 gas is non-toxic in its pure state.

- SF6 gas is non-flammable, hence there is no chance of fire hazards.

- Since it runs flawlessly, it requires less maintenance.

SF6 circuit breaker faults

- By-products formed from SF6 gas during arcing are toxic to the environment but are mostly recombined into SF6

- Decomposed sulfur hexafluoride is toxic.

- SF6 is an expensive gas so these circuit breakers are expensive.

- Leakage of sulfur hexafluoride from joints must be constantly monitored.

- Requires special transportation and preservation of gas quality.

- SF6 is heavier than oxygen and can cause difficulty breathing.

- Recombination and regeneration of SF6 gas requires additional equipment.

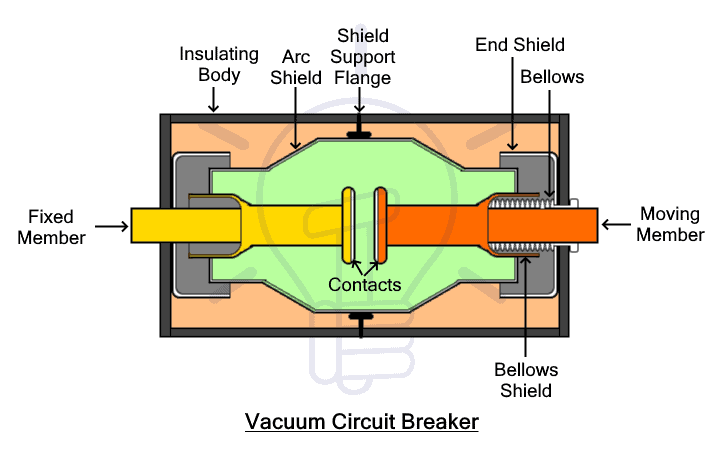

A vacuum circuit breaker or VCB is a type of circuit breaker that uses a vacuum as the arc cooling medium. Vacuum has very high dielectric strength and far more arc quenching properties than any other medium. He could quickly recover his buffer power. Due to its high dielectric strength, a VCB requires a very small gap between its contacts to prevent re-braking. The vacuum pressure used in the VCB ranges from 10^ -7 to 10^ -5 torr (1 torr = 1mm of Hg). It is suitable for medium voltage switching from 22kV to 66kV.

The switching of the current- carrying contacts and the arc interruption occurs inside a closed chamber called a vacuum breaker . Its external insulating body is made of glass or ceramic material. It consists of fixed and moving contacts surrounded by an arc shield. The arc shield is used to prevent the deterioration of the insulating strength of the vacuum by preventing ionized metal vapors on the inner side of the outer insulating body. The moving member is connected to a controlled mechanism (for movement) using steam. The bellows completely seals the vacuum chamber and prevents any leakage.

The operation _of a VCB is quite simple, the arc interruption occurs within the vacuum at the first zero current. When an error condition occurs, the contacts are disconnected. During separation, the contacts do not separate at once but their contact area is reduced which eventually reduces to a single point. The amount of current passing through this single point heats the contact and vaporizes (reducing the dielectric strength of the vacuum) to create an arc medium. Thus the arc is created. At the next zero current, the conductive metal vapors again condense onto the contact surface and the dielectric strength of the vacuum is restored. Since the contacts are separate and there are no fumes between them, the arc cannot re-strike. In simple words,

Since the arc is created due to the ionization of the contacts, its material plays a vital role in keeping the CB reliable and maintenance-free. Therefore, the contact material of the VCB must have the following properties

- It must have a high electrical conductivity to avoid overheating at normal load currents.

- It must have a high thermal conductivity to dissipate the large heat generated during bending.

- It shall have high arc withstanding capabilities and low current cutting level.

- It should have low resistance with high intensity.

The connectors are made of a copper alloy such as bismuth copper, lead, copper and chromium.

Advantages of VCB

- Void is the absence of matter and therefore the VCB has no fire hazards

- The vacuum has very high dielectric strength and superior arc quenching properties compared to air and SF6.

- Due to its high dielectric strength, VCB requires a small contact gap to extinguish the arc.

- VCB is compact and requires little installation space.

- It is maintenance free hence reliable and has a long life.

- It does not make any noise during the operation.

- There are no toxic exhaust gases.

- Its action is very fast.

- It is suitable for frequent use.

- It can break all kinds of fault currents.

- Because there is a vacuum, the control mechanism requires less energy to move the contacts.

VCB defects

- Single vacuum breaker can only cut up to 38kV.

- To interrupt voltages above 38 kV, multiple discharge breakers must be connected in series.

- It is not economical for voltages above 38 kV because it requires more VCB and increases the total cost.

- If void is lost, the VCB becomes useless.

Low voltage AC circuit breakers

Circuit breakers that are used to break and make circuits of less than 1000 volts are called low voltage circuit breakers. The definition of low voltages depends on their context of use. According to IEC, low voltage refers to the voltage below 1000V. An arc created at such voltages is easily quenched. Low voltage circuit breakers are mostly used for residential and industrial applications.

Here are some low voltage AC circuit breakers:

- Miniature circuit breaker (MCB)

- Molded Circuit Breaker (MCCB)

- Residual current circuit breaker (RCCB)

- GFI or GFCI (Ground Fault Circuit Interrupter)

- Arc fault circuit interrupter (AFCI)

- Joint (bundled) trip circuit breakers

- Magnetic circuit breakers

- Thermal magnetic circuit breakers

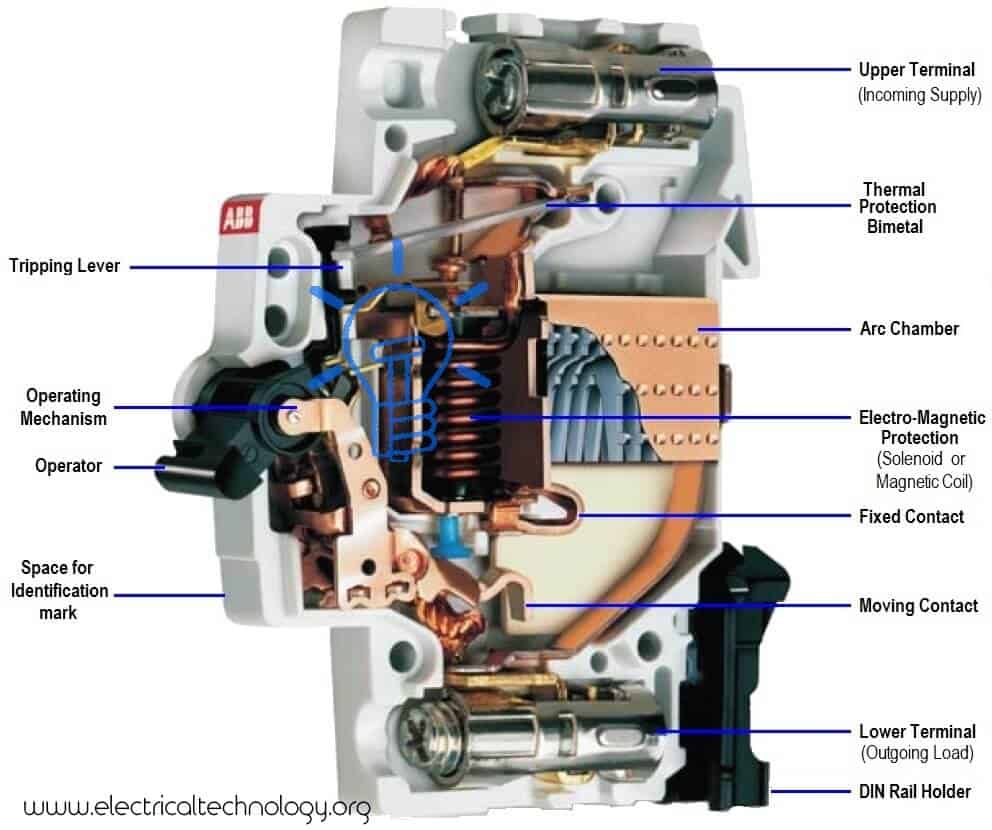

Miniature circuit breaker (MCB)

MCB or Miniature Circuit Breaker is an automatically operated electromechanical device used to protect a circuit from overloading or short circuit. It breaks or opens the circuit when the current flowing through it exceeds its rated limit. The MCB is used to protect a 240/415V AC low voltage circuit with a wide range of current ratings below 125V.

The MCB does not trip (shut off) immediately, instead there is a time delay between the occurrence of the fault and the contacts breaking. Generally, they are designed to have a time delay of less than 2.5ms for short circuit and 2sec to 2min for overload. It is to ensure that the CB does not move every time with a temporary surge or start of the inductive load due to higher inrush current from such loads as electric motors.

The MCB does not have adjustable flight characteristics. Whereas the fracture mechanism can be either thermal or thermomagnetic in operation. Thermal breaking mechanism is used in case of overload while magnetic cutting mechanism is used in case of short circuit.

The MCB is enclosed in an insulating casing. The fixed and moving contacts made of copper or silver alloy are connected to the two terminals for current supply. There is an arc duct consisting of multiple conductive sheets called arc dividers that dissipate the arc energy. While the operating mechanism, as previously discussed, is of two types: thermal and magnetic.

The thermal tripping mechanism consists of a bimetallic strip (made of two different metals with different thermal expansions) usually made of steel and copper and is used to break a circuit in the event of an overload. When the above rated current limit begins to flow through the metal strip, it heats up and begins to expand due to its bending and actuation of the latch to separate the contacts.

The magnetic tripping mechanism consists of a coil or solenoid that produces a magnetic field when current flows through it. In the event of a short circuit or a very high current, the solenoid produces a strong magnetic field to pull the lever and disconnect the contacts.

Molded Circuit Breaker (MCCB)

MCCB or molded case circuit breaker is an electromechanical circuit breaker having very high current ratings of up to 2500A. It is used in applications where the current ratings exceed the range of the MCB (Miniature Circuit Breaker). It provides a thermomagnetic separation mechanism wherein the thermal mechanism is used for overload and magnets are used for short circuit conditions. It can cut current about 10k-200kA.

The best and most notable part of the MCCB is that its flight characteristics are adjustable to any current rating. MCB has no such feature. MCCB is suitable for applications where the normal current is higher than 100A. They are installed in industries.

The MCCB can have a fixed or interchangeable trip unit. The trip unit is responsible for breaking communications when the fault condition is met. It provides three types of functionality:

Overload: Overload occurs when the current exceeds a certain limit for a certain duration. This current can damage equipment and wiring and create a fire hazard. MCCB uses bi-metallic tape for overload protection.

Bimetallic tape is made of two types of metal that have different rates of thermal expansion. The inrush current is used to heat the tape either using a heating coil or conducting it directly through it. The bar heats up and produces and thus the mechanism kicks in.

Short circuit: Short circuit current refers to the fault current in the system due to a deteriorated line, broken exposed wires contacting, or damaged equipment. The current flow due to a very large short circuit is much more than the overload current.

The short circuit must be cut off in the shortest possible period of time. The MCCB can trip SC currents of up to 10K-200K A in a duration of 0.04 seconds.

Manual conversion

The MCCB can also act as a manual switch to turn the power supply on/off for the circuit. It can cut off the power supply manually in case of emergency or maintenance.

Advantages of MCCB

- The MCCB has an adjustable trip setting.

- It can cut very large currents.

- It has a mobile flight unit.

- It has a very small tripping time and thus fast switching during fault current.

- It also provides remote on/off feature.

- It has a compact design and takes up less space.

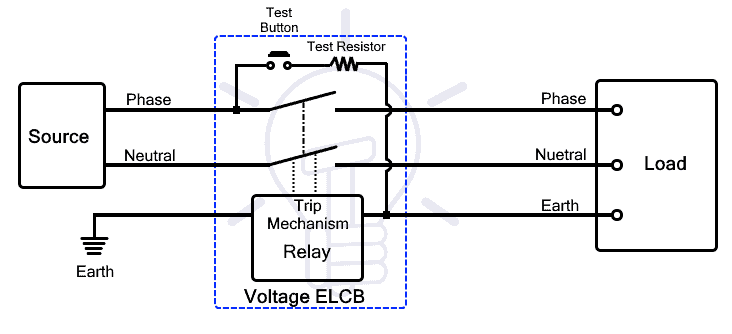

Earth Leakage Circuit Breaker (ELCB)

ELCB stands for Earth Leakage Circuit Breaker. It is a type of circuit breaker that breaks its circuit upon sensing the leakage current. Leakage current is caused by insulation failure in the wires and can flow through a person’s body and cause an electric shock. Hence they are used to protect against electric shock. They do not provide protection against overload or short circuit. Therefore, they must be used in series with the MCB.

There are two types of ELCB;

- ELCB voltage

- Current ELCB (also known as RCCB)

Both types of ELCB detect leakage current but their sensitivity and the level of protection they offer are different. The voltage ELCB was invented before the current ELCB. The voltage ELCB is lower than the current ELCB. Therefore, to avoid confusion, the voltage ELCB has been renamed as ELCB while current ELCB has been renamed as RCCB.

ELCB voltage

The ELCB voltage operates on the voltage level between earth and the body of the instrument. The ELCB has an additional grounding terminal which is connected directly to the load or the body of the instrument. If the load body touches the live wire, it may cause an electric shock when touched.

The relay is connected in series with the grounded wire. This relay senses the potential difference between the body and the ground. It trips the circuit breaker if there is a significant amount of current flowing through the ground wire due to potential difference.

However, the ELCB cannot sense leakage current if a person touches a live wire. Therefore, the ELCB cannot provide protection for other types of leakage current. Moreover, it also requires a ground connection which is not required in the RCCB discussed later.

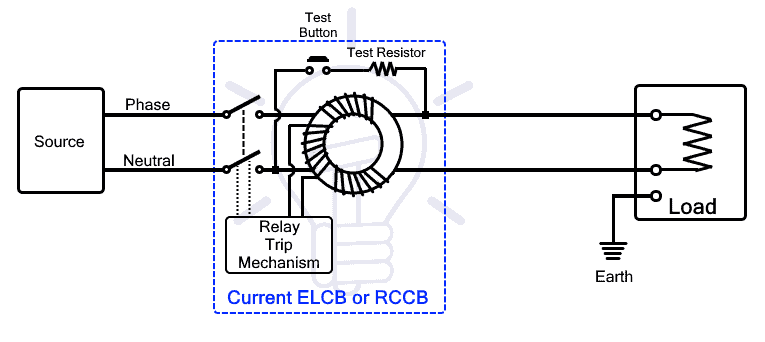

Current ELCB (RCCB)

The current ELCB is generally known as RCD or RCCB. A residual current device (RCD) or residual current circuit breaker (RCCB) is a type of ELCB that breaks the circuit if the current leaks. Helps protect against electric shock or downed line.

Current leakage occurs when current flows in an unintended path. Under normal conditions, current flows to the load through a hot or live wire and flows from the load through the neutral wire. Current is leaking if the current is flowing through the ground wire or through the body of the person connected to the ground.

The RCCB works according to the principle of Kirchhoff current law, according to which the amount of current entering a circuit must be equal to the amount of current leaving the circuit. It constantly monitors the current in the hot wire and the neutral wire. The difference between these two currents is called the residual current. When there is a fault in the circuit, the residual current will trip the circuit breaker.

The live and neutral wire pass through a zero-sequence current transformer (it is used to sense a current imbalance between the two wires). The live and neutral wire are used for current in and out to the circuit respectively. Since the amount of current is equal in both wires, their flow cancels each other out. When the imbalance is caused by any ground fault, the resulting flux creates a voltage in the current transformer connected to a relay that breaks the circuit.

Type AC RCCB

This type of RCCB is sensitive to AC only and cannot provide protection against DC or any other waveform.

Type A RCCB

This type of RCCB is sensitive to alternating current as well as to a pulsating or square waveform

Type B RCCB

This type of RCCB provides protection against AC current up to 1000 Hz, pulsating DC as well as smooth DC.

About RCCB

- It does not provide protection against overload or short circuit.

- Does not protect against line-to-neutral electrical shock.

- It is only sensitive to specific waveforms and does not guarantee protection against other waveforms.

Residual current overcurrent breaker (RCBO)

RCBO or residual current surge breaker is a circuit breaker made from a combination of RCCB and MCB. It provides both RCCB & MCB functions i.e. protection against residual current or earth fault current and overcurrent.

Residual current: is the imbalance in current between the live and neutral wire due to current leakage to earth. RCBO provides protection against it to prevent electric shock.

Surge: means to increase the current when the current exceeds its limit. This happens for two reasons: overload and short circuit .

Overload : It is caused by huge current draw above rated current for a long time which can damage wires as well as components.

Short circuit : Occurs when the live and neutral wires come into direct contact with each other. An enormous amount of current flow can damage electrical equipment.

RCBO provides protection against both types of faults which are offered individually by RCCB & MCB.

Arc fault circuit interrupter (AFCI)

AFCI stands for Arc Fault Circuit Interrupter; It is another type of low voltage circuit breaker that provides protection against arc faults. An electric arc fault is a high-energy discharge between two faulty conductors. These arcs can generate enough heat to start a fire and cause serious damage to property and life. AFCI breaks the circuit when any arc is sensed in the connected circuit.

Brackets are created due to improper or loose connections in cables or cables damaged due to nails, twisting or kinking, etc. A loose connection in PowerPoint or old cables may cause an electric arc. It can start a fire and disable or damage any sensitive electronic equipment.

The arcs generate a non-periodic waveform which is detected using a sensitive logic circuit. Distinguish between normal arc (occurs during switching) and arc fault. Once an arc is detected, the circuit trips the power supply but cannot prevent the first arc. Although it can prevent those following and avoid potential fire hazard.

Common trip circuit breakers (combined)

A common circuit breaker or group circuit breaker is an assembly of two or more circuit breakers that simultaneously disconnect multiple circuits from fault in only one circuit. The external operating handle of the individual cutters is bolted together. It is usually used in a three phase system where a single phase fault must cut off the power supply to all phases. It is also used to increase the current ratings of a CB by connecting it in parallel.

Types of circuit breakers based on the Tripping Curve

Circuit breakers can be classified into 5 types based on tripping characteristics and instantaneous tripping current.

Type B circuit breakers

This type of MCB travels instantaneously at 3 to 5 times the rated current. It is more sensitive than other types and should not be used in places with elevations higher than the stated limit. Otherwise, you will trip frequently even under normal conditions. It can tolerate low current. It is suitable for resistive loads in residential applications such as lighting and other resistive elements.

Type C circuit breakers

This type of MCB travels instantaneously at 5 to 10 times its rated current. It is used for high inductive loads which have high inrush current such as small motors. It is suitable for handling inductive loads in industries.

Type D circuit breakers

This type of MCB trips instantly at 10 to 20 times the current rating. It can withstand the maximum increase in the MCB case for a short time. They are used for very high inductive loads like heavy duty electric motors etc. in industrial and commercial applications.

Type K circuit breakers

This type of MCB travels instantaneously at 8 to 12 times its rated current. They are used for heavy inductive loads used in industries.

Type Z circuit breakers

This type of circuit breaker breaks the circuit instantly at 2 to 3 times its rated current. They are the most sensitive and are used for medical equipment and sensitive semiconductors that are susceptible to slight surges.

DC circuit breakers

As the name suggests, these CBs are used in DC circuits. Direct current or unidirectional direct current has no natural zero current, that is, it is continuously stable and has a positive value. Unlike AC which has several zero currents (no power) which used to quench the arc very easily. DC does not have such natural zero currents, so arc quenching is difficult.

A DC circuit breaker uses an arc-pulling magnet to lengthen and facilitate its quenching. However, there are some lower voltage circuit breakers that can be used for both AC and DC circuits.

HVDC circuit breakers

HVDC stands for High Voltage Direct Current. It is used to safely break and protect against fault currents in HVDC circuits.

The voltage level in HVDC is very high up to 800 kV. At such a DC voltage, the arc generated is very strong and has no natural zero current. While disconnected, the fault current can damage the breaker connection as well as everything in the circuit.

In order to break the circuit under fault conditions and quench the arc safely in HVDC CB, the following steps must be ascertained

- Create an artificial zero intersection

- Dissipation of energy stored within the LC circuit

- withstand voltage between its connections

- Prevent arc reset

HVDC circuit breakers use an LC circuit in parallel to introduce artificial zero currents into the circuit. Before disconnecting the contact, the current must be reduced to zero. An LC circuit containing a charged capacitor connected in opposite polarity drives the current in the opposite direction bringing the current to zero. At this point, the contacts are separated and the arc is quenched at zero current.

Depending on the installation site

The circuit breaker can be classified based on the installation site.

Internal circuit breakers

As the name suggests, these circuit breakers are designed for indoor use within buildings. They have a weatherproof enclosure. They are designed to operate at low and medium voltage levels.

External circuit breakers

This type of circuit breaker is designed to withstand the harsh outdoor environment. Its outer shell is relatively strong to withstand the harsh environment and wear.

Based on the exterior design

According to the general design of CB, that is, their switching unit is either in ground potential or not, they are divided into the following two types. These types are only applicable to high voltage CBs.

Dead tank circuit breakers

In such high voltage cables, the interrupt unit is enclosed in a metal enclosure located at the ground potential. It requires a large amount of oil or other insulating medium to isolate the interrupt unit from the grounded container.

Insulated bushings are used for line and load connections allowing a bushing current transformer to be installed on them to reduce additional cost.

Live tank circuit breakers

A live tank CB mounts the interrupt unit on top of an insulator with line voltage present. It reduces the size of the circuit breaker and also uses a small amount of oil or other insulating media (only used for arc cooling).

CBs can be used in series to operate at a higher voltage at a lower cost. However, it requires a separate CT, unlike a CB dead tank which can use a CT bushing.

Depending on the operating mechanism

Based on the operating mechanism used to trip the circuit, CB can be divided into the following types.

Spring operated circuit breakers

These cables use the mechanical energy stored inside the spring to actuate the contacts. The spring is compressed by any means of energy storage and retention using a latch. Sensing the trip signal, the latch releases the spring thus triggering the contacts.

Compressed air circuit breakers

The pneumatic circuit breaker uses compressed air to actuate its contacts. The air compressor compresses the air and stores it inside a tank which is released on signal to break or make contact.

Hydraulically operated circuit breakers

A hydraulic circuit breaker uses a piston and hydraulic fluid to actuate its contacts.

Circuit breakers are magnetic

This CB uses an electromagnet or solenoid to produce a magnetic field which is used to pull or push the latch that holds the spring etc.

Hydraulic circuit breakers

The CB uses both magnetic and hydraulic CB features to perform the tripping action.

other circuit breakers

Motor Protection Circuit Breaker (MPCB)

A motor protection circuit breaker or MPCB as its name suggests is a type of circuit breaker specifically designed for the safe operation and protection of electric motors. It protects the electric motor from several breakdowns

Line Fault: The MPCB protects the motor from short circuits, line-to-ground and line-to-line fault. The display cuts off immediately upon sensing these defects.

Overload: Drawing an excess amount of the above rated current is called overload, and it can damage the windings. MPCB protects motors from overloading and can be adjusted.

Thermal Delay: Overloading causes the windings to heat up and therefore it is necessary to wait for them to cool down before restarting them. The MPCB provides an adjustable heat delay.

Unbalanced Phase: The MPCB provides protection against an unbalanced 3-phase system or phase loss that can cause motor damage.

The MPCB provides thermal and magnetic protection for overload and fault currents respectively. Unlike other circuit breakers, the MPCB protects against a three-phase unbalanced system and phase loss fault. It can withstand electric motor inrush current up to 10 times its rated current. It is also used to isolate the power supply to the motor for maintenance purposes.

Automotive circuit breakers

Automotive circuit breakers are used just like normal CB devices to protect against fault current in vehicles. They are classified into the following types based on their resetting mechanism.

Type 1 Auto Reset CB

As the name suggests, the Type 1 CB is automatically reset after tripping without user intervention. CB returns this automatically when the error is removed. Type 1 CBs are used for low voltage applications where it is difficult to manually access a circuit breaker.

Type 2 manual reset CB

Type 2 CBs have a built-in reset button that is used to manually reset the circuit breaker. These CBs have a visual indicator that shows the status of the breaker. The fault must be tracked down and removed prior to a Type 2 CB reset.

Type 3 press to trip CB

Type 3 CBs offer manual circuit tripping at the push of a button. It breaks the current without shutting down the source such as a motor or a battery which makes it ideal for safety reasons. These CBs are used for high current applications.

Types of circuit breakers

Gahzly website to buy power circuit breakers

When we say Gahzly website, we are talking about one of the most famous Arab websites, which was able in a very short period of time to achieve a very high demand for purchases from it by people from different parts and sectors of the Arab world.

On the Gahzly website, you will find power circuit breakers and all the products that you may need in your home, starting with those for kitchens or bathrooms, but even those for gardens. You will find them in this wonderful site.

So, if you were lost before and you don’t know where to go in order to buy your products on the Internet, now you have the perfect solution, and you only have to go to the Gahzly website and start choosing the products you want.

What are the features of Gahzly for purchasing power circuit breakers?

What are the features of Gahzly for purchasing power circuit breakers?

Since we are talking about a site that is preferred by many people around the world, there is no doubt that it is a site full of various features and characteristics, and for this we have decided to dedicate our next paragraph in order to indicate the most prominent features of the Gahzly site.

Among the most prominent features of the site, we find that there is proportional prices. On the Gahzly website, you do not have to worry about the imaginary prices of products, as is the case with most sites that display their products on the Internet.

The price of product delivery is very reasonable and not expensive, just as the site accepts delivery to various countries, without forgetting that it accepts free shipping on some products.

Among the advantages of the site, we also find that there is the high quality of its products, as it is impossible to find a poor-quality product. Rather, the Gahzly website deals with major companies, Philips, for example, and other famous brands, so you have to remove from your mind the idea of poor quality of one of the products.

Also, one of the advantages of the site is that it does not specialize in one type of product, but rather you will find various types of products on it, for example, electrical appliances, hand tools, mechanical devices, paints, packages for establishing apartments and many other types.

Gahzly also accepts what is known as the shopping cart, which makes it easier for you to filter the products you want to buy and put them in one package in order to be able to pay with the click of a single button.

Multiple payment methods are accepted.

18 Different types of circuit breakers – their construction, operation and applications

We are pleased to have you visit our pages on social networking sites, where we publish exclusive offers on our website.

Our Facebook page here .

Our Twitter account here .

Leave a Reply

You must be logged in to post a comment.