Connecting electrical wires – 8 best ways

Connecting electrical wires – 8 best ways

The following are the factors that determine the choice of connector:

- Base material (brass or aluminum).

- Working conditions (on the street, in an apartment, in water, on land, in the ground, under normal conditions).

- Number of conductors (two, three, four, etc.).

- Cross section (identical, different).

- Basic structure (single wire or multi-wire).

Based on these factors, the most appropriate and correct method is chosen. To begin, consider the materials from which you can connect the electrical wires in the junction box.

Content:

- Current methods

- Using terminal blocks

- Spring stations

- Installation of PPE covers

- Crimping with special sleeves

- Welding or welding

- Misrepresentation and isolation

- Nut clamp

- Use bolt

- What to do if there are many wires?

- What if the veins have different sections?

- Combining stranded and solid wires

- How to do work in water and land

Current methods

- Use terminal blocks ;

- Installation of spring terminals (Wago);

- Installation with personal protective equipment (plastic covers);

- Crimping with sleeves.

- welding

- twist;

- Installation of “nuts”;

- Use screws.

Consider the nature, advantages and disadvantages of each of the methods!

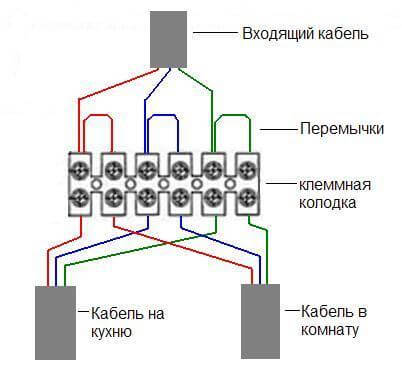

Using terminal blocks

Terminal blocks They are plastic products , inside there is a copper sleeve, and it has screws on both sides.

In order to connect two wires to each other using a terminal block, it is necessary to insert each side into the end of the product and tighten them completely with screws (forcefully). This connection method is often used in junction boxes, as well as in the installation of chandeliers, switches and sockets.

Advantages:

- Low price of terminal blocks;

- Fast and convenient installation of products;

- good bonding;

- Aluminum can be connected to copper.

cons:

- Often, the terminal blocks are of poor quality, which can lead to breakage of the connector during installation.

- The ability to combine only two connectors with each other.

- It is not recommended to use terminal blocks for tightening aluminum and copper winged connectors. This is due to the high fragility of aluminum and the thinness of the conductors of the stranded wire: when tightening the pins, the contacts can be damaged.

- When using welding, reliability will be much higher.

- Multi-wire flexible cores for connection in screw terminal blocks of any design (including circuit breakers, sockets, etc.) are crimped with lugs of type NSHVI and the like.

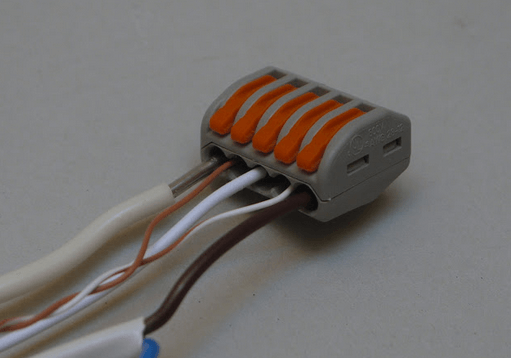

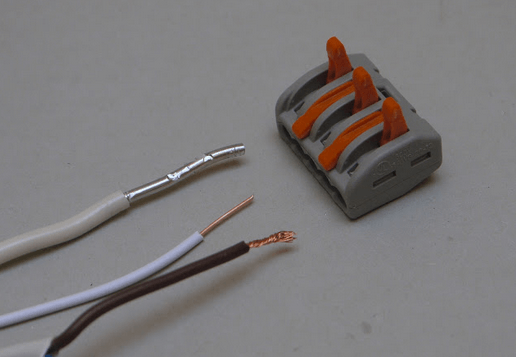

Spring stations

Spring loaded wago terminals appeared on the market relatively recently and have undoubtedly become the most effective and safest connectors.

The difference between trolley terminal blocks and traditional terminal blocks is that a special mechanism is used to connect the electrical wires, not a screw. This lifting mechanism allows you to gently fix the product without damaging it. In order to independently connect the trolleys, it is necessary to strip the insulation and insert the cores into the hole.

We draw your attention to the fact that there is a cart of disposable and reusable terminal blocks. The first option involves a one-time connection, which will not be possible to restore during the repair of electrical wiring: it will be necessary to cut the trolley, fix the problem and install a new terminal block. Reusable wago terminals are more expensive, but can be used to easily disconnect a contact if necessary. “

Wago Advantage:

- Depending on the model of the terminal block, it is allowed to connect copper and aluminum conductors, as well as protect aluminum from oxides with quartz and petroleum jelly paste.

- The ability to connect several cores at the same time (more than two);

- Wago clips allow you to fix a stuck thin wire without damage;

- The terminal blocks are very compact;

- The work does not take much time;

- good bonding;

- The car terminal block has a special hole that allows you to control the operation of electrical current using a screwdriver.

Only drawback – the high cost of the terminals, but this is not critical even for home wiring. It is also important to note that WAGOs are not suitable for wiring of powerful consumers, such as an oven or electric stove. These terminal blocks are more suitable for switching circuits in the outlet line, as well as lighting sets.

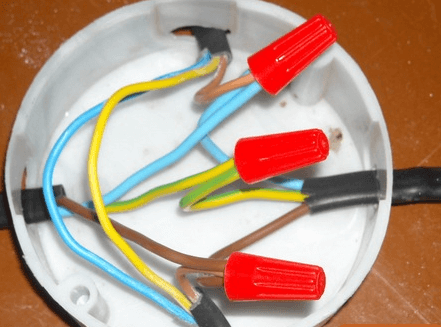

Installation of PPE covers

PPE for connecting insulating clips . The products are ordinary plastic covers that have a special spring inside, which holds the wires.

Most often, these covers are used to connect the cores in junction boxes.

Benefits of using these products:

- Low cost of personal protective equipment;

- The caps are made of non-combustible materials, so spontaneous combustion of electrical wires in the place of twisting will not occur;

- Fast download;

- Hats have a wide range of color shades. For example, if the wires do not have color marking , the use of PPE can be observed phase, zero and ground (using a white, blue and green cap).

cons:

- Relatively poor quality of insulation and installation;

- It is impossible to connect aluminum to copper.

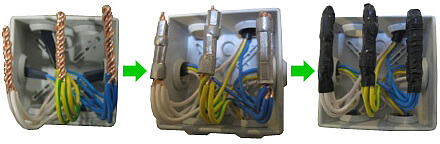

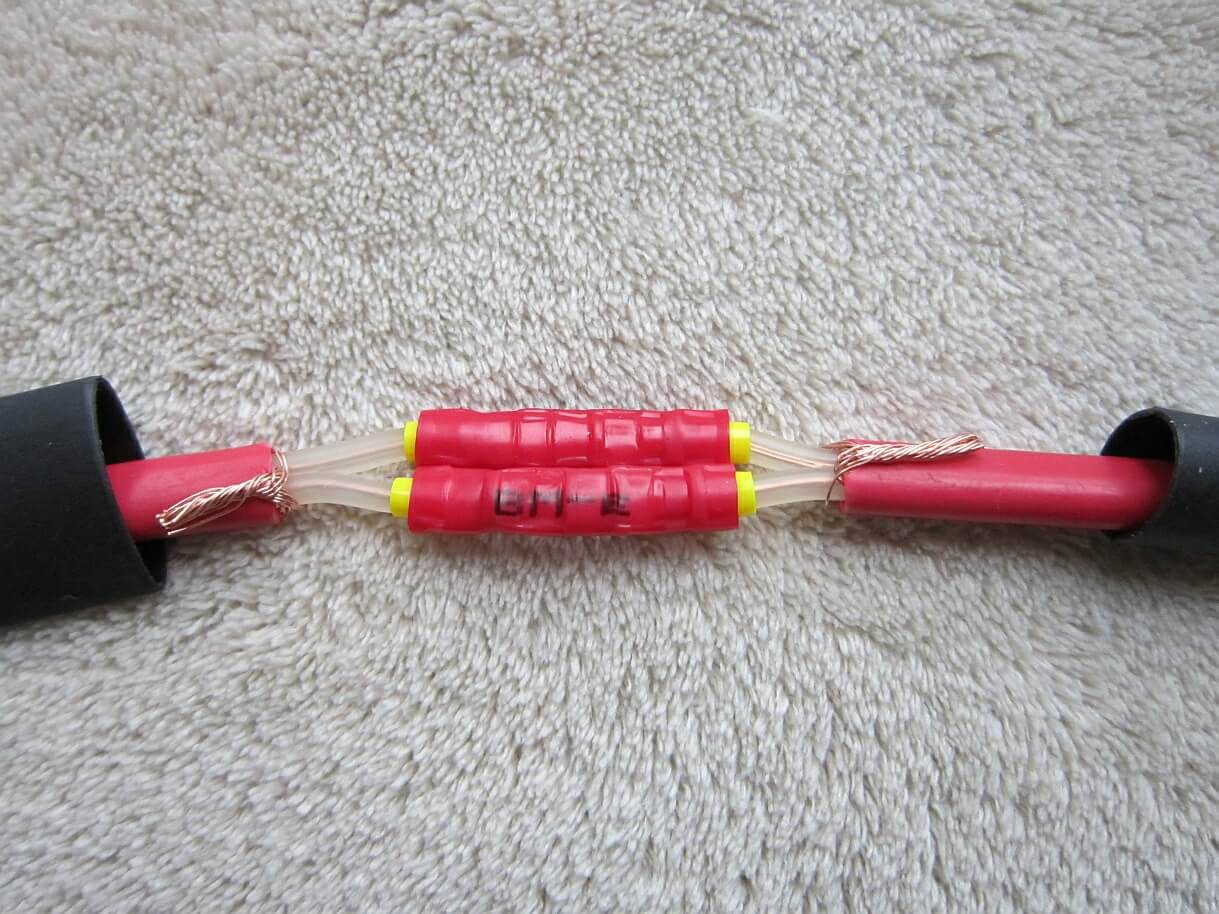

Crimping with special sleeves

Crimping with sleeves is one of the most reliable options. Its essence lies in the fact that bare veins are placed in a special tube – a sleeve, and are segmented with effort. After crimping, the jacket is carefully insulated using heat shrink tubing (Cambrian) or electrical tape.

Conductors can be directed from different sides of the pipe or from one side. In the first embodiment, their joint should be approximately in the middle of the sleeve, and in the second, the cross-section of all cores (total) should not exceed the cross-section of the sleeve.

Advantages:

- High quality connection and insulation;

- The sleeve has a low cost.

cons:

- Disposable scabs (1 piece). If repair is necessary, the bushing must be cut and discarded, after which a new bushing must be installed.

- A special tool is needed for connection: press pliers and a pipe cutter (in order to shorten the sleeve if necessary). You can also use a special stripping tool that has a compact crimping device.

- It is possible to compress aluminum and copper wires only with a special sleeve, which is not often seen on sale.

- Electrical work will require more time.

Welding or welding

This method is the highest quality of all. In order to connect the two wires together in a junction box, it is necessary to carefully strip their ends, twist them and dip them in molten solder. Furthermore, the cores must be immersed in a soldering bath. After that, they must cool and, finally, be insulated with cambric or electrical tape.

Or soldering with a soldering iron, but in this case a 3-4x spike with a cross section of 2.5 square meters lived. Mm hard. Therefore, in order to solder thick wires, it is necessary that the soldering iron has a thick copper tip with a good heat capacity and a power of 40, and preferably 60 watts or more.

We draw your attention to the fact that it is strictly forbidden to cool the solder in cold water, as in this case, the bonding quality will noticeably deteriorate (due to the appearance of microcracks).

Advantages of welding method – excellent contact quality and reliability.

cons:

- The need for a special tool – a soldering iron, and therefore the ability to work with it;

- complexity of work;

- One-piece welding;

- Restriction in terms of use in accordance with the PUE;

- Weld resistance increases over time, affecting voltage loss and electrical conductivity.

Based on this, it is advisable to avoid welding by using more modern joining methods.

It should be noted that there is also a connection of electrical wires by welding. The process is similar, but requires the use of a welding machine instead of a soldering iron and, therefore, soldering skills.

These two methods of connecting wires in the junction box are discussed in detail in separate posts:

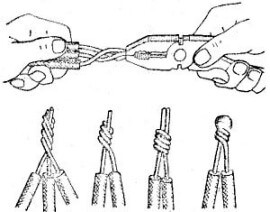

Misrepresentation and isolation

The old “grandfather” method consists of twisting the veins together. The essence of the work lies in the fact that the conductors are carefully stripped and twisted with pliers, after which the place of twisting is insulated.

Advantages:

- simplicity of electrical work;

- Lack of material costs.

cons:

- Poor quality of intravenous ligation.

- The connection of aluminum and copper products is unacceptable.

Most often torsion wires are used in temporary wiring installation. For insulation, it is recommended to use cambric. According to the PUE, this method of wiring the junction box cannot be used in rooms with high humidity and in a wooden house.

Nut clamp

The “nut” is a cable clamp that has two special plates and four bolts at the corners, as can be seen in the photo below. For nut wire connections it is necessary to strip both ends of the wire and screw them into the plate, then put them on the carbolite sheath.

Advantages:

- Low clamping cost.

- The process of installing the “nut” does not cause any difficulties;

- Copper and aluminum conductors can be connected;

- Good enough insulation.

cons:

- It is necessary to tighten all screws periodically;

- The “nut” dimensions are not suitable for installation in a junction box or other compact places.

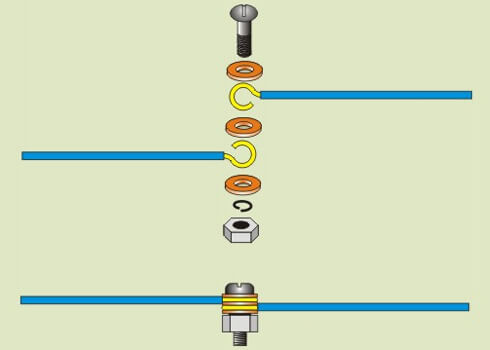

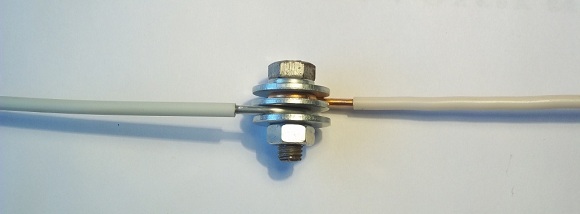

Use bolt

A simple, but nonetheless effective option for connecting electrical wires together is with a nail. All you need is to have a short bolt, 3 washers and a nut on hand.

A washer is put on the bolt thread, then the stripped core is wound, after which another washer – core – washer is put on (as shown in the diagram above). At the end, the bolt is carefully tightened with a nut and insulated.

Advantages:

- Simplicity and minimum cash costs;

- Aluminum and copper conductors can be connected.

The disadvantages are as follows:

- Low quality installation

- need to spend a lot of insulation;

- The bolt dimensions will not fit in the junction box.

We have figured out the existing methods of wiring the box, now we will consider the remaining issues that are important for this topic.

What to do if there are many wires?

When connecting two contacts, problems usually do not arise. But what to do if at the same time it is necessary to combine three, four or more?

In this case, it is recommended to choose the following connection options (from best to worst):

- Use wajo end blocks;

- Crimping with sleeves.

- welding

- Twisting using sizy.

- Twisting and wrapping with electrical tape.

The order of connecting the wires for each of the methods we have considered in detail above. We highly recommend using the first option, as it is one of the most modern and efficient. At the same time, the cost of the vagina is not very high, and the wires last for more than 30 years.

What if the veins have different sections?

To connect the wires of different sections of the junction box, it is recommended to use all the same terminal blocks for the car, or a cheaper option – ordinary terminal blocks. In this case, it is necessary to carefully tighten the cores with a screw or fix them with a flag, and that’s it, the work is finished.

We draw your attention to the fact that if the wires are made of different materials, it is necessary to use special pads with internal paste, which prevents oxidation of the wires. These pads include wago products.

Also, battens of different sections can be repaired by welding.

Combining stranded and solid wires

Connecting single and multi-core wires individually does not have any features, so you can use any of the above methods.

In order to carry out bonding, you must choose one of two options: car ends or welding. It all depends on your preferences and the advantages and disadvantages of each method we have presented.

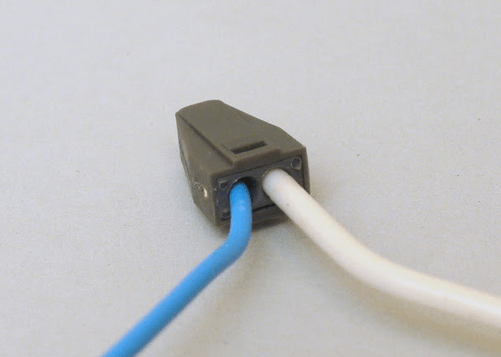

How to do work in water and land

During electrical work, a situation often occurs when it is necessary to connect wires under water or in the ground. Now we will briefly consider the features of each of the cases!

In water (for example, when installing a submersible pump), it is recommended to use the following technology. First of all, the ends are soldered, after which the welding place is carefully insulated with hot melt adhesive, over which shrink wrap is worn. If everything is done competently and honestly, the joint will be tight and secure. Otherwise, it may happen. Short circuit and power outage.

To connect the electrical wire into the ground (for example, after mechanical damage), it is recommended to use the above method (hot melt and heat shrink), but it is better to protect yourself and use the following method. Attach the cable ends to the terminal block, install a sealed junction box, then carefully fill the box with a special silicone sealant. We draw your attention to the fact that the underground path must be additionally laid in a pipe or channel to ensure reliability of rodent protection!

It is also recommended to ground the damaged ends of the wires into the ground using a special cable sleeve, as in the photo below!

That’s all I wanted to tell you about this problem! In case there is no nuance, we advise you to watch visual video lessons. Hopefully, you now know what type of connectors are most commonly used for a particular application condition, as well as how to connect wires in a junction box.

If you have any inquiry, please contact us freely and we will be happy to serve you.

Jezli website for purchasing electrical appliances

When we say Jeezly website, we are talking about one of the most famous Arab websites that was able, in a very short period of time, to achieve a very large demand for purchases from it by people from various parts and sectors of the Arab world.

On the Jeezly website, you will find a joint look and all the products that you may need in your home, starting with those for kitchens or bathrooms, but even those for gardens, you will find them on this wonderful site.

So, if you were lost before and did not know where to go to buy your products on the Internet, now you have the perfect solution, and all you have to do is go to the Jezli website and start choosing the products you want.

What are the features of Jeezly ?

What are the features of Jeezly ?

Since we are talking about a site that is preferred by many people around the world, there is no doubt that it is a site full of various features and characteristics. Therefore, we have decided to devote our next paragraph to pointing out the most prominent features of the Jezli site.

One of the most prominent features of the site is the proportionality of prices. On the Jeezly website, you do not have to worry about the imaginary prices of the products, as is the case with most sites that display their products on the Internet.

The price of delivering products is very reasonable and not expensive, and the site accepts delivery to various countries, without forgetting that it accepts free shipping on some products.

One of the features of the site is also the high quality of its products, as it is impossible to find a poor quality product. Rather, the Jezli website deals with the major companies, Philips, for example, and other famous brands, so you must remove from your mind the idea of the poor quality of one of the products. Another advantage of the site is that it does not specialize in one type of product, but rather you will find various types of products on it, for example, electrical appliances, hand tools, mechanical devices, paints, packages for establishing apartments, and many other types.

Jeezly website also accepts what is known as the shopping cart, which makes it easy for you to filter the products you want to buy and put them in one package in order to be able to pay with the click of a single button.

Accepts multiple payment methods.

We are pleased that you visit our social media pages, where we publish exclusive offers on our website.

Our Facebook page is here .

Our Twitter account is here .

Leave a Reply

You must be logged in to post a comment.