Electrical cables and their types

Electrical cables and their types

Electrical cables and their types. Methods of extending electrical cables and their types are among the most important foundations that you must know because of their direct relationship to the field of electricity in extending homes, transmission lines, and power.

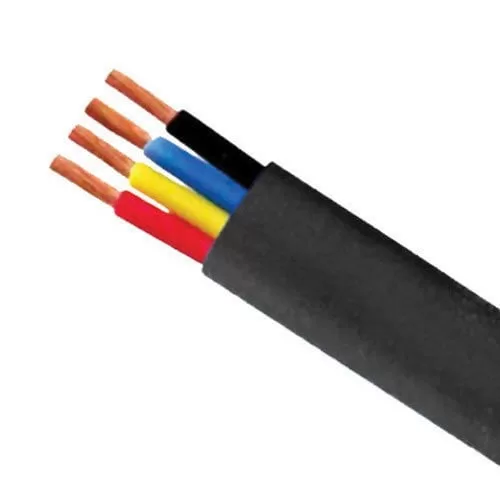

The method and types of connecting electrical cables overlap in home, commercial and industrial extensions and external transmission networks. Electrical cables are available in different types and diameters. When choosing an electrical cable, it must be taken into account that it is suitable for the type of extension (external/internal) and the capacity of the electrical loads (home/commercial). / industrial); Based on this, the most appropriate cable for connection is chosen.

Follow this article with us to learn about methods of extending electrical cables and their types.

Electrical cables and their types

Definition of electrical cables (electrical connectors)

It is a tool for transferring electrical energy produced from renewable and non-renewable electrical energy plants to consumption areas, such as residential complexes, factories, public and private institutions, and hospitals.

The electrical cable conductor is made of copper or aluminum, and is coated with an insulating material to isolate the conductor from its surroundings.

Electrical cables

Factors affecting the choice of electrical cables

There are several ways to extend electrical cables and their types to suit the location, as follows:

- Extension inside the wall.

- Extension inside external pipes.

- Underground extension.

- Extension on private channels.

- Insulation of cables and connectors.

- Extending factories using Cable Trays.

- Maximum operating voltage of the cable.

- The maximum value of the short circuit current and its duration, meaning that the electrical cable must withstand the short circuit current.

- Cable length.

- Maximum temperature cycling tolerance: voltage drop.

Electrical cable extension route

Electrical cable extension route

The method chosen for extending conductors and cables depends on several different factors, the most important of which is the nature of the project. For example, in an industrial project, it is preferable to use Cable Trays, so that the conductors and electrical cables are placed on these exposed stands, and thus the surrounding air works to escape the heat of the electrical conductors and cables.

There are several types of methods for laying electrical cables:

- Internal extension (inside the wall): such as home and commercial extensions.

- External extension through channels: The extension is carried out inside plastic channels installed on the wall.

- Extension on stands called Cable Trays: used inside factories and large buildings.

Internal extension (inside the wall)

External extension through channels

Extension on stands called Cable Trays

Electrical cable insulators and their types

Electrical cables and conductors shall be insulated using one of the following materials:

Polyvinyl chloride (PVC)

This type of insulator is suitable for low voltages and low temperatures, is cheap, and is widely used in most internal wiring compared to other types of insulators.

Cross-linked polyethylene (XLPE)

This is another type of insulator, and it is suitable for external extensions because of its advantages of withstanding high temperatures, short circuit currents, and also resistance to moisture. But the disadvantage of this type is avoiding severe bends during extension.

ethylene propylene (EPR)

It is made of rubber. Rubber is water-resistant, but it cannot resist flammable materials such as gasoline and oil.

Electrical cable insulators and their types

Simple cable components

Electrical cables withstand maximum short current and duration

Electrical cables withstand maximum short current and duration

Each electrical cable is manufactured with specific specifications to withstand the maximum short-circuit current within a specific range, so before choosing the appropriate cable, it must be studied to what extent it can withstand short-circuit currents within seconds. So we can set the maximum short-circuit current that the circuit breaker is designed to protect the electrical cable without it burning.

Impact of electrical cables with voltage drops

The longer the cable and the smaller its cross-sectional area, the greater the drop in voltage, and thus the greater the increase in the value of the electric current.

Instructions for extending electrical cables

- Ensure that there are no flammable materials.

- Avoid placing a single cable through which high currents pass inside a pipe, because it creates an induced current due to the creation of a magnetic field inside the pipe.

- Separate high-current power cables from low-current cables, such as telephone cables, Internet cables, and other low-current devices, with a distance of no less than 30 cm, to prevent magnetic interference.

- For external extensions, special protections must be placed for electrical cables.

Conclusion: When extending any electrical network, one must know the nature of the building and the type of electrical loads, and study the external and internal factors that may affect the choice of electrical cables and their types, in addition to the type of insulation.

Electrical cablesand their types

Electrical cablesand their types

We are pleased that you visit our social media pages, where we publish exclusive offers on our website.

Our Facebook page Here.

Our Twitter account Here.

Leave a Reply

You must be logged in to post a comment.