Hose Fittings

Hose Fittings

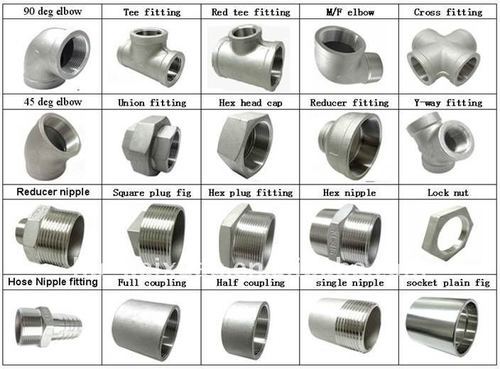

There are many types of Fitting available to the Motor Sport enthusiast. The options are diverse and it can be difficult to choose the most suitable type for your project. I take a look at them and highlight the key differences. This is our Oil Fittings overview.

What We Cover

What We Cover

I take a look at what is on offer and try to show the pros and cons of each. This is a review of a number of oil hose fittings that can be procured from many of the well known brands, not just parker.

We will compare similar aspects of each of the oil hose fittings, such as weight, size, suitability etc. I will use either -10 AN or 1/2 BSP examples for weight and size comparisons.

These are the areas covered:

These are the areas covered:

- Thread Types Commonly Used

- General guidance

- Aluminium Reusable

- Aluminium Push On

- Steel Push On

- Steel Crimped On

- Aluminium Crimped On

Thread Types Commonly Used

As well as deciding which type of fitting to use you may need to decide on the thread type. For automotive use the popular choices are AN / JIC or BSP. If you decide to use the aluminium fittings you will almost certainly be using the AN / JIC thread because this is the thread and sealing style commonly used with high performance equipment. BSP is more of a traditional thread and sealing style that is often only available in steel. In my experience your choice of thread will be influenced by the equipment you are connecting to. If you are migrating away from BSP to AN / JIC this can be done and it may require some adaptors to be changed.

General Guidance

Regardless of which oil fittings you decide to use their are some ‘golden rules’ that have been proven over time to reflect good practice, they are:

- Buy the most suitable specification fittings you can afford within your budget. This may mean having an over spec steel fitting rather than a cheap anodised aluminium fitting. Parts that are manufactured in an environment where making profits come before quality control should be avoided.

- Do your research before you buy.

Aluminium Reusable

As the name suggests these aluminium oil hose fittings can be used repeatedly. They can be used time and time again as long as they are installed and removed properly. With this key feature in mind it is important to purchase an oil hose fitting that has been manufactured to a high standard or at least to a standard that will really allow you to reuse them.

Key Information

- The majority of Aluminium reusable oil hose fittings are manufactured as AN / JIC fittings. BSP is poorly catered for.

- The parker versions have a compact full flow elbow on angled fittings. This can be a compact as a forged elbow. They take up less space.

- A -10 AN 90º version (parker) weighs 71g.

- This style of oil hose fitting is used with a braided hose. Examples are stainless steel braided hose (not Teflon), nylon braided hose and Aeroquip Startlite hose.

- Hoses can be assembled by the customer (see ‘Useful Resources’).

Aluminium Crimped On

There are a number of aluminium crimped on hose fittings available from various suppliers. At parker we offer a version based upon the Aeroquip Startlite hose and the matching aluminium hose fittings manufactured by Eaton. This hose assembly is very light and highly regarded by professionals within the Motor Sport industry. The hose itself has some impressive qualities and when used with the lightweight crimped on hose fittings it results in a light hose assembly that has not been compromised to achieve the weight saving.

Key information

- Only available in AN / JIC versions.

- The -10 AN 90º version including the integral crimp ferrule is 85g.

- To be used with Aeroquip Startlite hose.

- Supplied as ready made hose assemblies to the customers specification.

- These are not re-usable. Once fitted to the hose they cannot be removed or reused.

Aluminium Push On

These too are reusable. The push on style of hose fitting works fine up to 200 psi. It is only when running at higher pressures that you risk the hose detaching from the hose end. That said some manufacturers quote 250 psi as being the maximum working pressure. These are a lightweight and reusable oil hose fitting that have an anodised finish. It is possible to have a custom colour applied to match your colour scheme.

Key Information

- The aluminium push on fittings tend to be AN / JIC. I am not aware of a BSP range being manufactured by any reputable company (or others).

- The parker versions have a compact full flow elbow on angled fittings. This can be a compact as a forged elbow. They take up less space.

- The -10 AN 90º version (a parker item) weighs 50g.

- Use with a quality push on hose. Note, the hose will have an imperial (fraction of an inch) inside diameter.

- The hose fitting cannot be removed from the hose unless the hose is cut or slit length ways.

- Hoses can be assembled by the customer (see ‘Useful Resources’).

Steel Push On

Again these are reusable. The working pressures are the same as the aluminium versions only because higher pressures can cause the hose connection to become a weak spot. However the actual steel hose fitting as a stand alone item can withstand huge pressures. For example a -10 AN 90º swept hose fitting has a maximum working pressure of 3,140 psi and a failure pressure of 9,420 psi. These are over engineered and robust hose fittings that are more industrial in appearance and capacity.

Key Information

Key Information

- Available in AN / JIC and BSP versions

- The -10 AN 90º swept hose fitting weighs 138g. That’s just over 2.5 times the weight of the aluminium version

- The swept angled hose fittings take up more room than the aluminium versions.

- Hose requirements are the same as the aluminium push on oil hose fittings quoted above

- The hose fitting cannot be removed from the hose unless the hose is cut or slit length ways.

- Hoses can be assembled by the customer (see ‘Useful Resources’).

Steel Crimped On

These are steel hose fittings that have a thinner wall than the steel push on hose fittings. They are as light as the aluminium equivalent. These are secured to the hose by a metal collar that is crimped (hydraulically compressed) around the end of the hose whilst the hose fitting is positioned inside of the hose. These are made to order based upon overall hose assembly length and the orientation of angled hose ends. It is possible to use these with a regular hose or to have stainless steel over braid applied to the hose before crimping.

Key Information

- Available in AN / JIC and BSP versions.

- The -10 AN 90º version including the crimp ferrule weighs 70g.

- Used with imperial sized hose.

- Supplied as ready made hose assemblies to the customers specification.

- Not re-usable once they have been crimped onto the hose.

lightning

We are pleased to have you visit our pages on social networking sites, where we publish exclusive offers on our website.

Facebook page here.

Twitter account is here.

Leave a Reply

You must be logged in to post a comment.