How to find the right heat shrink tubing to use

How to find the right heat shrink tubing to use

A comprehensive range of heat shrink tubing products

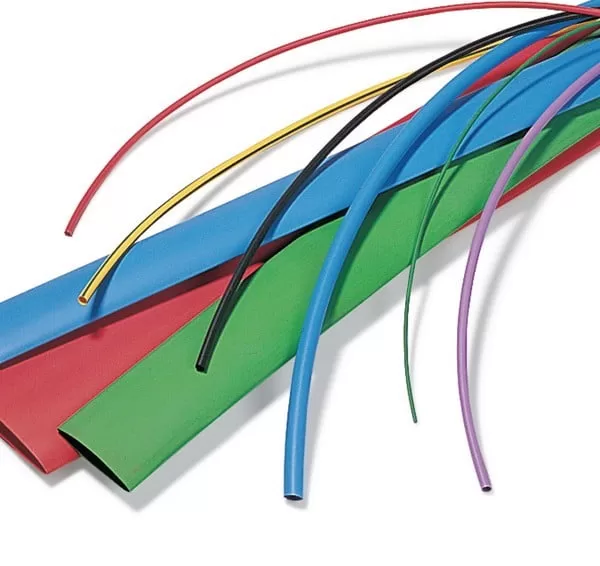

From colored heat shrink tubing to adhesive lined heat shrink tubing and molded heat shrink tubing,

From colored heat shrink tubing to adhesive lined heat shrink tubing and molded heat shrink tubing,

Gahzly Company offers a comprehensive range of products in different sizes of heat shrink tubes that meet the highest international standards.

We offer heat shrink tubing in different colors, sizes, wall thicknesses and materials (fluoropolymers, polyolefin, PTFE and many more)

…We offer heat shrink tubing pre-cut and on reels.

The case also includes heat shrink end caps and heat shrink molded figures.

- Product overview

- Cleaning heat shrink tubing

- Adhesive lined heat shrink tubing

- Heat shrink tubing kits

- Polyolefin heat shrink tubing

- Heat shrink tubing sizes

- Waterproof heat shrink tubing

- Heat shrink tubing is heat resistant

- White heat shrink tubing

- Hot air guns

- All heat shrink tubing

What is heat shrinkage?

Meaning of heat shrinkage: the process of applying heat,

For example using an electric or gas heat gun,

To shrink expanded plastic pipes or shapes back to their original size.

A distinction is made in this regard between the recovered dimension (original size) and the supplied dimension (expanded size).

Heat shrinkage is used in many electrical industries and applications

– For example to insulate cables and protect them from heat, corrosion, chemicals or water. Watch this

Heat shrink tubing for your application

Heat shrink tubing for your application

Not sure if a heat shrink product is right for your specific application?

Enter the known dimensions into our online heat shrink calculator.

Will check the size. We recommend that heat shrink tubing shrink at least 20% and no more than 80% of the supplied dimensions.

Colorful heat shrink tubing

Different colors for visual recognition

Besides black heat shrink tubing, Gahzly offers a wide range of colored tubing.

These are ideal for color coding different connectors or cables.

The demand for orange is also increasing.

This is a result of the increase in high voltage power systems installed in vehicles.

Sometimes, it is important to see through the heat shrink tubing.

Clear tubes are ideal for water lifting labels applied to cable jackets.

Gahzly offers the following colors:

Gahzly offers the following colors:

Clear/transparent

white

red

orange

black

Green color

blue

…and much more. View all of Gahzly’s heat shrink tubing products here and select the right color for your application.

Why are heat shrink tubing clear/transparent?

Many cables are color coded or have identification tags printed on them

– For example in public buildings such as airports and hospitals but also in tunnels and means of transport such as railway vehicles, ships and aircraft.

Clear tubes are often used to insulate wire jackets while keeping identification marks visible.

This is known in the trade as oversleeping.

Printable heat shrink tubing

Printable heat shrink tubing

Printable single wall tubes are used to clearly identify conductors, for example to mark live, neutral and ground.

Printable single wall tubes are used to clearly identify conductors, for example to mark live, neutral and ground.

It has a low shrinkage temperature and is available in many colors and sizes. It is also flame retardant and listed.

Thanks to these properties, it meets and exceeds many industry standards.

Another example of thin-walled flexible polyolefin hose is flame retardant

Also Convenient: Equip your ShrinKit with a wide range of sizes, colors and lengths.

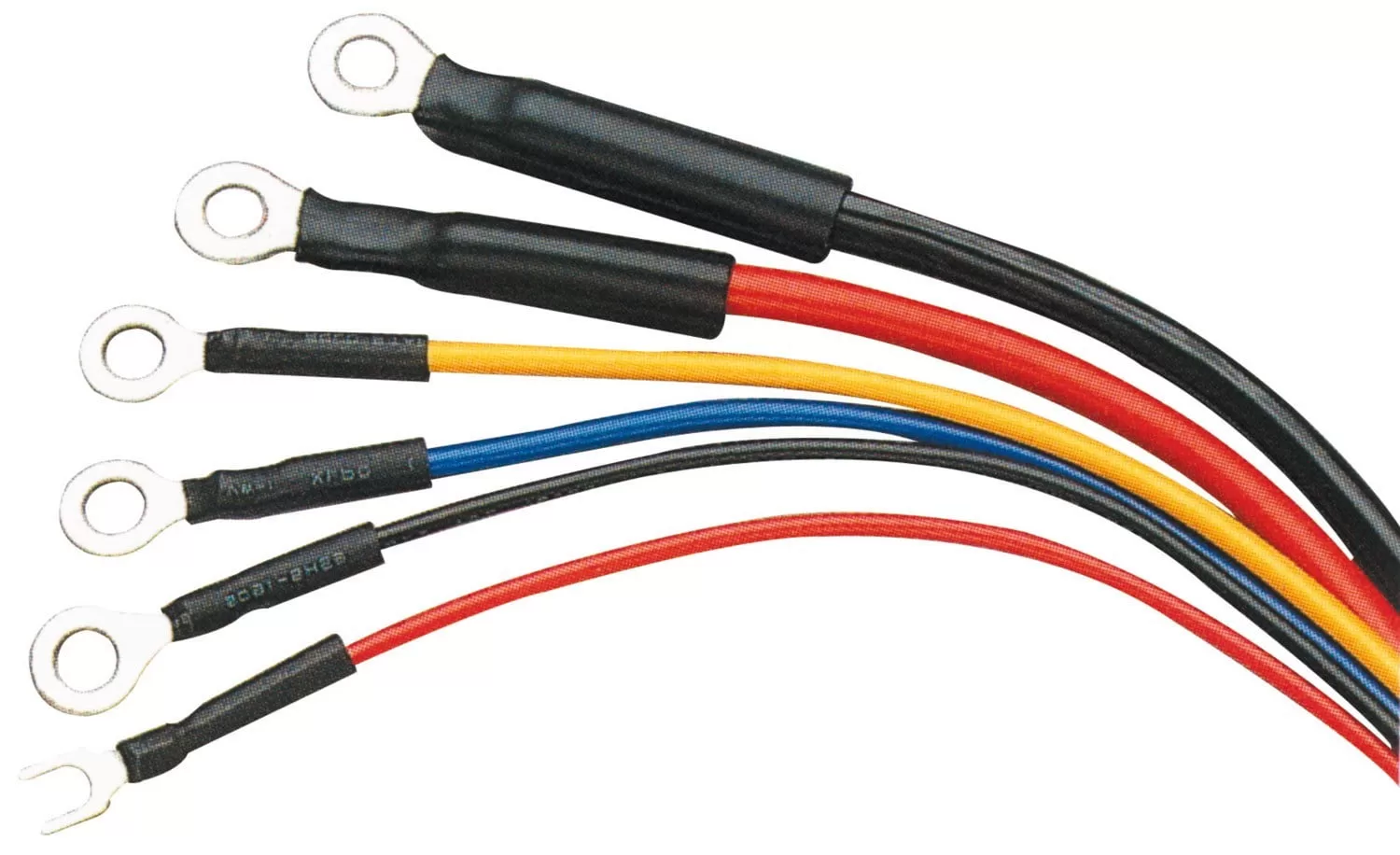

Adhesive lined heat shrink tubing

For excellent environmental sealing and durability

Adhesive lined heat shrink tubing has an inner layer of flexible glue to seal the outer tube and wire covering against any water ingress.

It also gives the electrical application additional mechanical strength.

Medium-wall glue-lined shrink tubing is ideal for use underground or around buried wires.

Gahzly Company offers a wide range of pipes lined with adhesives with different shrinkage ratios and properties.

What are adhesive tubes?

Adhesive lined tubes are also known as double wall tubes.

Adhesive lined tubes are also known as double wall tubes.

Because here you have a combination of a cross-linked outer shell (polyolefin) and an inner layer of adhesive.

When heated, the inner adhesive wall melts and flows.

This process creates an adhesion layer that ensures a tight fit to the wire, wire or connector.

Glue lined heat shrink tubing is ideal for producing strong, weather-resistant seals with additional mechanical strength and excellent protection against corrosion.

Heat shrink tubing

Middle wall, adhesive lined heat shrink tubing with a 4:1 shrinkage ratio, provides reliable insulation and moisture protection for low voltage cable joints and ends.

Protects polyolefin based from moisture and other environmental influences: for above and below ground electrical applications.

How much to repair RMS cables

RMS is a sleeve around the bushing used for cable repair and binding.

RMS is a sleeve around the bushing used for cable repair and binding.

The adhesive wrap around cable repair and water seal system is quick, labor-saving, tight-fitting and durable.

It is ideal for repairing buried cables where traditional heat shrink products are difficult or impossible to install.

Simply wrap the pre-slit RMS repair sleeve around the damaged cable insulation and secure it in place with the supplied rail and seal the conduit.

Apply heat with a gas torch to shrink and melt the adhesive liner, completing the environmental seal.

As a simple visual aid, thermochromic paint spots on the outside of the shell disappear when sufficient heat is applied.

Here you can find all the adhesive lined products from Gahzly at a glance.

Heat shrink tubing sizes

How to choose the right heat shrink size?

Shrink tubes have different shrinkage rates.

This describes the maximum volume change during the contraction process.

For example, if the shrink tube size is reduced to 50%, the shrinkage ratio is 2:1.

Special applications, such as connector assembly, require larger diameter shrink tubing with a high shrinkage rate.

Wall thickness also plays an important role in finding the right product.

In general, it can be said that the thicker the cable and the greater the mechanical load, the larger the wall thickness of the shrink tube should be.

To find the right shrink tube for your application, our size calculator and wall thickness calculator can help.

Size calculator

Not sure if a heat shrink product is right for your specific application? Enter the known dimensions into Thermal Shrinkage Calculator Get Ready.

He will check the size for you. We recommend that the cover shrink at least 20% and no more than 80% of the dimensions supplied.

Wall thickness calculator

When heat shrink tube shrinks, the diameter changes as well as the wall thickness. Our Wall Thickness Calculator gives you an indication of the theoretical wall thickness for a given diameter.

ShrinKit Assorted Boxes

Gahzly offers pre-cut thin single wall heat shrink tubing in hand assembled kits. ShrinKit is a family of five sets of heat shrink tubing.

With a shrinkage ratio of 3:1, they offer ideal replacements for many different sized pipe requirements.

Selecting the required tube is easy as the content is clearly identified by size and length on the lid of the set box.

Material: Polyolefin

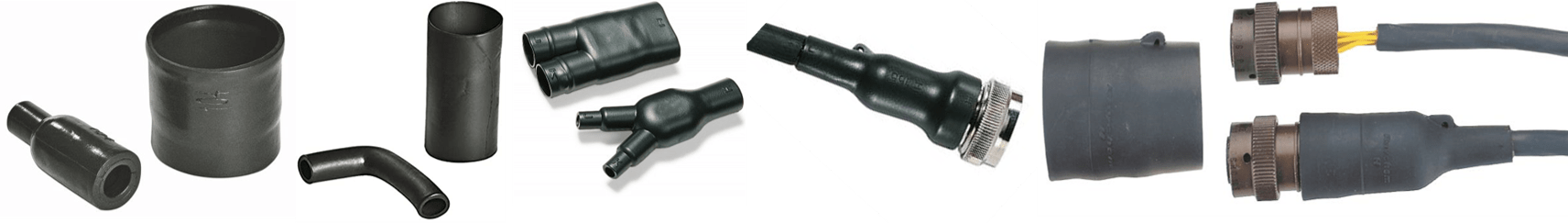

Heat shrink molded shapes

Forms with high dielectric strength, mechanical rigidity and superior resistance

From glass-shaped shoes and long outlet shapes,

From glass-shaped shoes and long outlet shapes,

to unidirectional shapes,

And six-way shapes or angular shapes and T-shapes,

Gahzly offers a large variety of shrink molded forms in different sizes and materials. These forms are used in various areas,

For example for applications in the defense industry.

Straight shrink boot with rib

The Helashrink series is designed for connections to circular notched adapters. The use of an additional inner flange ensures pressure relief.

The Helashrink series is designed for connections to circular notched adapters. The use of an additional inner flange ensures pressure relief.

In addition, the Helashrink series provides superior protection against environmental influences. This bottle-shaped solution is particularly used in the aviation industry.

See all Gahzly products here from the Glass Shapes product range.

Right angle shoe with rib

The Helashrink 1100 right angle series is used in conjunction with a circular notched adapter. It provides pressure relief and an environmental seal.

The Helashrink 1100 right angle series is used in conjunction with a circular notched adapter. It provides pressure relief and an environmental seal.

In addition to right angle shapes, Gahzly also offers many parts with other shapes for different applications:

For example 45 degree shoes, Y ports, VG style shapes, T shapes and many more.

See all Gahzly products here from the Right Angle Shapes product group.

End caps

Helashrink 1600 series is used to seal cable ends during storage and transportation. Adhesive lining provides an excellent environmental seal. Optionally, End Caps can be fitted with air valves for compression cable applications.

Helashrink 1600 series is used to seal cable ends during storage and transportation. Adhesive lining provides an excellent environmental seal. Optionally, End Caps can be fitted with air valves for compression cable applications.

Twisted cases

The Helashrink 313C series provides strain relief and is used for circular notched adapters. Thanks to the adhesive lining, it provides excellent environmental sealing.

The Helashrink 313C series provides strain relief and is used for circular notched adapters. Thanks to the adhesive lining, it provides excellent environmental sealing.

The complex design provides flexibility for different cable exit angles. The Helashrink 313C series is primarily used in military and general performance equipment.

See all Gahzly products from the Low Profile Convolute Boots range here.

Did you know? Gahzly also offers a high-performance two-component adhesive. H

It has tremendous adhesive strength and very good resistance to most chemicals and fuels.

The adhesive is particularly popular for use with molded shapes and is available as a single cartridge (V9500) and as a complete kit. For this purpose, a special applicator gun is also available.

More information, a selection guide to finding the right molded shape for your application and our full product range can be found in our Shrinkable Molded Shapes Product Guide.

Gahzly offers these hot air guns

Cordless heat gun – gas operated

Cordless heat gun – gas operated

For optimal curing of shrink tubes, Gahzly offers the CHG900 gas fired hot melt gun.

For optimal curing of shrink tubes, Gahzly offers the CHG900 gas fired hot melt gun.

. The cordless heat gun allows independent operation without an electrical power source.

So it can be used anywhere, for example outdoors or in remote places.

Common application areas include among many maintenance and repair work in the areas of:

Electrical installations

Railway industry

Offshore wind parks

The CHG900 hot air gun allows for easy 360 degree work at all angles

-Even top operation is no problem. The cordless heat gun also convinces in terms of ease of use.

In the event of malfunctions of the piezo ignition or gas nozzle, maintenance work can be carried out easily, independently and completely tool-free.

The most important benefits at a glance:

Instant heat: no preheat time

90 minutes run time: 3-4 times longer compared to rechargeable battery powered tools

ECO-FRIENDLY: Stainless steel gas cartridges once fully emptied are recyclable

360° OPERATION: Hands-free operation thanks to the built-in stand case

Outdoor qualified: even in the harshest conditions down to -8°C

Lightweight: The tool weighs only 440g and 555g with gas cartridge

Easy maintenance: tool-free and independently to minimize downtime

As an alternative to a gas-powered cordless heat gun, you can also choose an electrically powered one.

Hot air gun – electrically operated

The H6100 electric hot air tool is designed for applying thin to medium wall heat shrink tubing, end caps and molded shapes.

To obtain the best possible result of the shrinkage process, the tool is equipped with 3 different pushing nozzles.

Powerful 1600 Watt motor

The ceramic heating element allows temperatures up to +700°C

Safe use on the workbench thanks to the non-slip rubber ring

Built-in air filter, easy to clean

Frequently asked questions

What are the top tips for using heat shrink tubing?

Tip 1: When shrinking heat shrink tubing, it is recommended to start the shrinkage process in the middle section of the tube and then gradually move to one end and then from the middle again to the opposite end.

This helps you avoid trapping air under the tube.

Tip 2: Tubes also shrink longitudinally, that is, along their length.

You must take this shrinkage into account when cutting pipe into lengths.

Tip 3: It is possible to reduce lengthwise shrinkage by shrinking the ends first and then the midsection.

However, if you do this, air can get trapped, preventing the middle part from shrinking.

Alternatively, you can shrink the tube by starting at the most significant end and then slowly shrinking towards the other end.

Tip 4: If the object to be covered is metal or conductive of heat, care must be taken to ensure the object is pre-heated to avoid “cold spots” Or “cold signs”.

This ensures a tight and smooth fit to the tube.

Tip 5: When cutting heat shrink tubing and wrap sleeves to the desired length, take special care to ensure the ends are cut smoothly.

Poorly cut and irregular edges can cause heat shrink tubing and sleeves to split during shrinkage.

Tip 6: When choosing a tube size, it is important to consider the 80:20 rule.

This means that the pipe size must be chosen to allow shrinkage of a minimum of 20% and a maximum of 80%.

Detailed examples of how to choose the right heat shrink tube are available in the Insulation Products section of our catalog.

Tip 7: During shrinkage you should always make sure that the workplace is well ventilated and that you wear personal protective equipment such as gloves and goggles.

What are the most important parameters for correct heat shrink tubing?

Wall thickness:

The thickness of the material should be determined in millimeters after complete shrinkage.

“nominal” Specifies dimensions without any tolerances.

In general, you can distinguish between thin wall, medium wall and thick wall. Heat shrinkable tubing is also available with an adhesive liner.

This is also called double wall tubing.

Diameter:

For thin-walled pipe with a shrinkage ratio of 2:1 (standard pipe), the diameter is usually in inch sizes; 25.4 mm equals 1 inch.

Shrinkage Ratio:

Depending on the material compound used and the wall thickness, heat shrink tubing can be extruded to a different degree.

Shrinkage ratio indicates the rate at which the product shrinks (i.e. the diameter supplied in relation to the diameter recovered). It varies from 2:1 to 6:1.

The higher the height value, the larger the diameter of the body the tube can cover.

Consequently, fewer sizes of pipe are needed, which helps reduce inventory levels.

Longitudinal shrinkage:

Heat shrink tubing not only shrinks in diameter, but also shrinks in length.

This longitudinal change after shrinkage is referred to as a percentage.

Minimum shrinkage temperature:

Not all tubes shrink at the same temperature.

It strongly depends on the type of compound it is made of as well as the wall thickness.

Operating temperature:

Operating temperature varies depending on the type of pipe.

This depends on the compound used for the type of tube.

When choosing the right size, it is recommended to follow the 80:20 rule described above.

Heat shrink tubing is generally used in cable harness assembly.

This includes insulation, identification and mechanical protection against corrosion as well as aesthetic design.

Heat shrink tubing

We are pleased that you visit our social media pages, where we publish exclusive offers on our website.

Our Facebook page Here.

Our Twitter accountHere.

Leave a Reply

You must be logged in to post a comment.