Rice Mill Machinery – What It Includes

Rice Mill Machinery – What It Includes

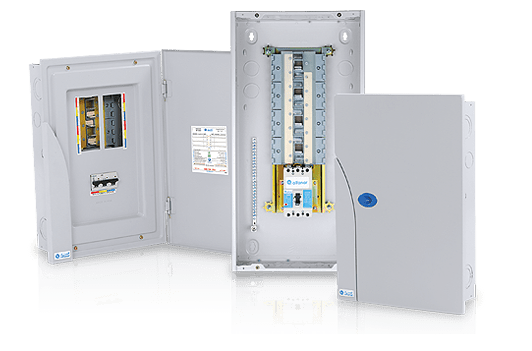

electric resistance

Rice milling is done to remove the husk and the bran layers from paddy rice to produce whole white kernels. This rice is sufficiently milled, free of impurities and contains minimum broken kernels.

Rice Huller

A rice huller is a machine used to separate husk (chaff) of grains from the rice. A machine built for this purpose known as Engelberg huller was designed in Brazil and is commonly used in Asia. The machine uses steel rollers to remove the husk.

There are three types of hullers according to their power usage: mechanical huller running on gasoline, electric rotary huller and hullers that can use several sources of power

Modern Rice Mill Machinery

The commercial mills use a multi-stage milling process which gives a high quality and output of rice.

The whole process has a number of machines that perform different functions.

Pre-cleaning

After rice has been harvested and dried, it must be separated from additional debris. Large mechanical separators sift and filter rice.

Husk Removal

The husk layer is removed from the paddy by friction and the process is called de-husking or de-hulling.

Types of husking machines

Steel Huller

It removes the husk and whitens the rice in one pass. Paddy is fed between a revolving steel shaft and a cylindrical meshed screen. These machines take approximately 15-20 hp to run.

Under Runner Disc Sheller

This machine has two steel emery coating discs. The upper disc is stationary while paddy flows from a centrally located hopper between the surfaces of the revolving lower disc and stationary upper disc. Resistance between the emery surfaces removes the husk leaving brown rice kernel.

This is an economical machine which produces a moderate amount of broken grains with a hulling efficiency of 85-90%.

Rubber Roller Huller

There are two rubber rollers (same diameter) as the name suggests which operate at different speeds to remove husk. One roller has a fixed position while the other is adjustable to meet the desired clearance. The adjustable roller rotates slightly slower than the fixed roller. The machine has an aspirator at the base to separate the hulls from brown rice.

This method has efficiency as high as 85-90 % with minimum broken grains.

Paddy Separation

The output from the huller is a mixture of paddy rice, brown rice, husk and broken paddy. The paddy separators then work by making use of the differences in specific gravity, buoyancy and size between paddy brown rice.

Polishing/whitening Process

The process of rice polishing is classified as Abrasive (less pressure and suited for larger grains) and Friction (forced against each other applying more pressure on the grain). We then get white rice irrespective of the process used.

Bagging

The fifth and final process is bagging in which a good rice mill will produce 50-60% head rice (whole kernels), 5-10% large broken and 10-15% small broken kernels. This is packed and bagged ready for transport.

Leave a Reply

You must be logged in to post a comment.