difference between air switch and knife switch 1

difference between air switch and knife switch

We often see electric bus switches for rural households including air switches and knife switches.

Knife switches are not common in urban households, but they are still very common in rural households.

However, in recent years, knife switches have gradually decreased and gradually replaced by air switches.

Two kinds of switches have their own advantages, so should you choose one when choosing a switch?

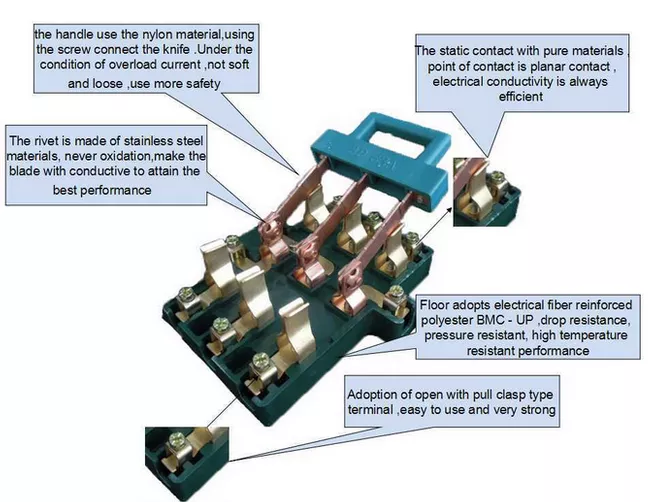

Knife switch internal structure

Knife switch internal structure

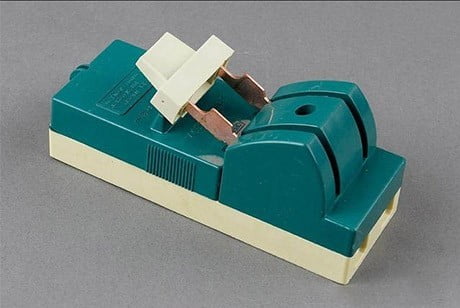

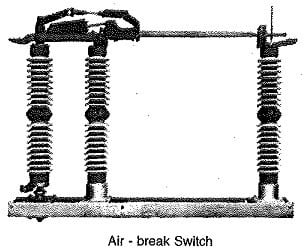

The above kind of switch is a knife switch often used in the family.

The above kind of switch is a knife switch often used in the family.

In addition to the separation function, it also has an overcurrent blown fuse (sheet).

This kind of switch has been used by most families because of its simplicity and low price. .

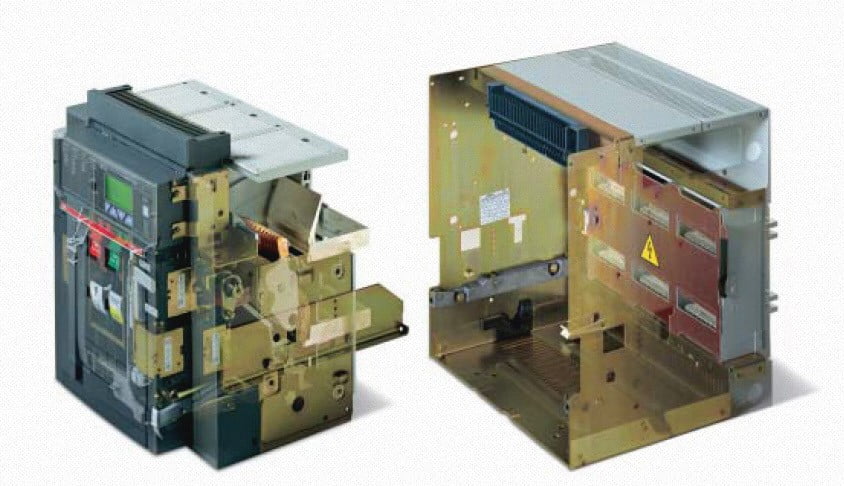

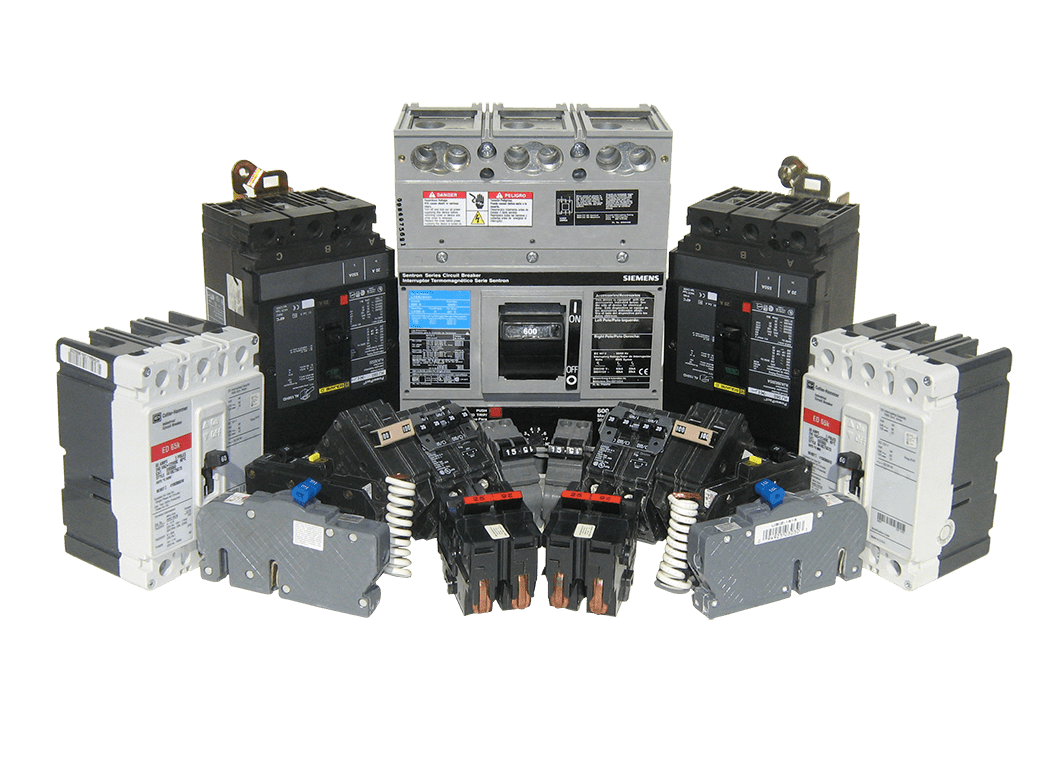

air switch

air switch

Air switch is also called air circuit breaker, and it is also a kind of switch, but this kind of switch has the function of extinguishing arc in addition to the function of separating circuit and overcurrent fuse of knife switch.

What is arc extinguishing? Extinguishing an arc means extinguishing an arc.

Arc is the electric spark we see when we close or open the switch.

Electric spark is a relatively slight discharge phenomenon in electric arc.

Because this air switch has an arc extinguishing function

, no electric spark can be seen when the switch is closed or opened, so its safety is better than that of a knife switch.

So should I choose a knife switch or an air switch?

It depends on the situation

First of all, knife switch and air switch have their own advantages and disadvantages:

Comparison of advantages and disadvantages of knife switch and air switch

| Switch knife | Air switch | |

| Advantage |

a. Low price

b. Can clearly see the breakpoint of the circuit

|

a. With arc extinguishing capability, high safety

b. After the circuit is disconnected, it is not necessary to replace the originals when closing, and the reuse rate is high

|

| Disadvantage | No arc extinguishing function, easy to see electric sparks, and the fuse needs to be replaced | The price is more expensive, the service life is shorter than the knife switch |

So, which switch you use depends on which effect you want.

If you want to be able to see the obvious disconnection point of the circuit

(can clearly see the disconnection point, people are more relieved) choose the knife switch.

After all, the disconnection point cannot be seen after the air switch is disconnected.

As for the disconnection, it depends on Whether the air switch is in the normal state;

if you want a higher safety and can extinguish the arc, then choose the air switch

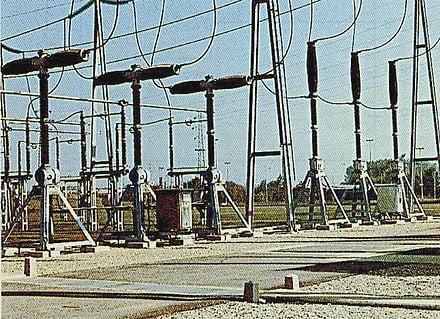

Air Break Switch: Types and Uses

An air break switch is a type of switch that makes use of air as a dielectric and arc quenching medium.

An air break switch is a type of switch that makes use of air as a dielectric and arc quenching medium.

The contacts of an air break switch open in the air.

Here, the arcing problem produced while opening the switch is resolved with the help of compressed air.

These types of switches are generally operated at low voltage levels,

i.e., voltage ranging from 450V up to 35kV.

The current range of air break switches lies between 800 A and 10KA.

The air pressure used by the air break switches ranges from 4 to 60 atmospheres.

It can also be said that an air break switch is a switchgear device that makes use of air as an interruption medium.

Working of an Air Break Switch

An air break switch is typically used to open the circuit under the load.

The arc that gets produced during the process of opening the switch is quenched in many ways.

It can be extinguished by moving the contacts away from each other or by supply interruption.

Usually, the arc is put out with the help of lengthening of the arcing horns present in the structure of the switch.

These arcing horns are nothing but the pieces of metals between which the arc is formed.

As the switch gets opened, the arcs tend to move far from each other, eventually breaking out.

The main components of an air break switch include an arc extinguisher

, a reservoir provided with a supply of compressed air, and an electro-pneumatic actuator.

The arc extinguisher is connected to the compressed air reservoir with the help of an insulated line.

It is used to quench the arc produced between the movable and the fixed contacts.

The de-energized electromagnet tends to open the air blast valve through a system of various pneumatic devices.

This helps supply the compressed air from the reservoir to the arc blowout chamber through the airline.

This compressed air tends to act on the piston of the movable contact and separates the movable contact from the fixed contact.

The arc that gets formed due to the opening of the contacts of the switch is required to be extinguished.

The compressed air from the chamber is used for the purpose of arc quenching.

The compressed air is directed through the outlets of the contacts to the gas escape channels.

After some time, the air enters the cylinder of a pneumatic actuator and quenches the arc.

After the arc extinguishes, the compressed air actuates the piston and breaks the isolating switch contacts.

The contacts are closed and the incoming of the compressed air is then cut off.

When the electromagnet gets energized, the valve opens and the compressed air is allowed to pass through the insulated airline.

The air enters the cylinder, acts on the piston, and closes isolating switch contacts.

Some of the air break switches are manufactured with air-filled isolating switches.

Such switches consist of contacts that are packed in an insulated casing.

The switch gets filled up with compressed air after being disconnected.

Types of an Air Break Switch

Types of an Air Break Switch

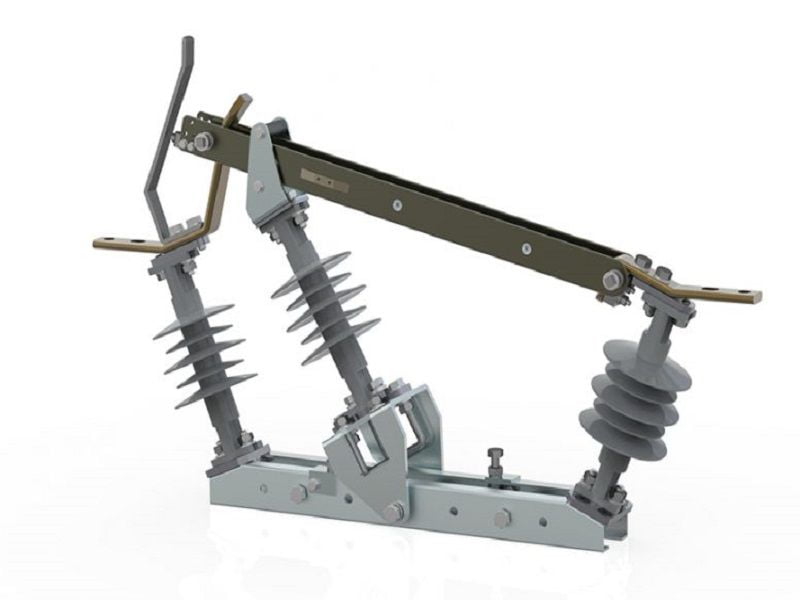

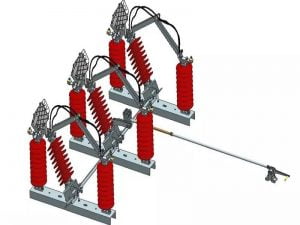

The air break switches can be broadly classified into two categories,

namely single-pole air-break switch and the gang operated air-break switch.

Single-Pole Air Break Switch

A single-pole air break switch provides an opening for only one conductor.

The working of a single-pole air break switch is similar to that of a normal air break switch.

Gang Operated Air Break Switch

Gang Operated Air Break Switch

A gang operated air break switch is used when the opening of more than one conductor at a time is required.

Here, all the switches tend to open and close together.

Uses of an Air Break Switch

Uses of an Air Break Switch

An air break switch is used in a number of commercial and industrial applications as given below:

1. Air break switches are typically used for switching and isolation purposes.

2. Air break switches are generally installed in the distribution networks as

a switching point to make or break connections between cables, transformers, and other high voltage electrical devices.

3. Air break switches are used in overhead power transmission lines.

Here, these switches are mainly used to perform on/off switching

by connecting the power system of a part of the overhead line to the main distribution line or

by disconnecting it from the main distribution line.

This allows the user to simply isolate a part of the overhead line without affecting the rest of the power transmission system.

4. These types of switches can also be used in power generation lines.

5. In certain power distribution systems, air break switches tend to provide crucial point isolation.

6. It is typically used to provide overcurrent and short circuit protection.

7. They are used in industrial plants for various control and safety operations.

Advantages of an Air Break Switch

Advantages of an Air Break Switch

An air break switch is advantageous in the following ways:

1. An air break switch is more effective than ordinary switches.

2. The reliability of air break switches is significantly high.

3. Air break switches can be operated manually as well as automatically depending on the requirement.

4. The maintenance of air break switches is relatively easy and cheap.

5. The air break switches are capable of fast breaker and switching operations.

6. These switches do not cause fire and explosion hazards.

7. An air break switch does not require a compressor.

8. These switches allow the user to maintain the stability of the operation.

Disadvantages of an Air Break Switch

Certain limitations or disadvantages of an air break switch are listed below:

1. They are quite heavy and bulky in nature.

2. The air break switches are less efficient for deionizing and lengthening action at high currents.

3. These types of switches are not suitable for modern power systems.

4. Air break switches require high capacity equipment for the storage and production of compressed air.

5. There exist chances of air leakage resulting in reduced pressure.

6. Air has comparatively lower arc extinguishing properties.

7. There are chances of a high rate rise of re-striking voltage and current chopping.

Air Break Switch – Types and Uses

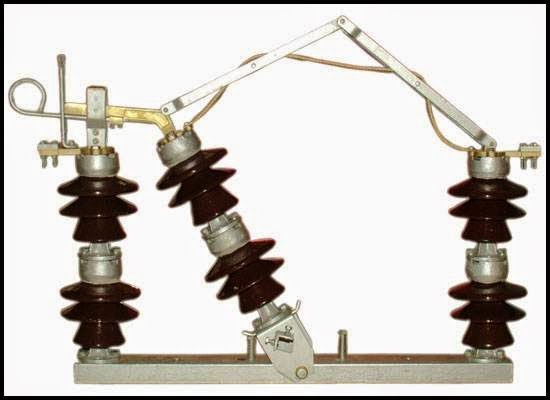

An “air break switch’ is a switchgear device that uses air as the dielectric.

An “air break switch’ is a switchgear device that uses air as the dielectric.

Air Break Switches (ABS) are widely installed throughout distribution networks for use as both isolation or switching points.

They are usually employed in outdoor installations.

Special Arcing Horns are provided to quench the arc which occurs when the current is interrupted.

These switches are usually operated by a handle which is located at the ground level.

Their operation can also be mechanized.

Use of Air Break Switch

Use of Air Break Switch

Air Break Switch Disconnectors are a vital part of any overhead line network,

providing crucial points of isolation.

Most overhead line networks are designed so that when a fault occurs or maintenance work needs

to be carried out it is relatively simple, by means of a systematic series of switching operations,

to isolate a certain section of the overhead line.

When this switching process is carried out it is absolutely imperative

that the Air Break Switch Disconnector is reliable and effective.

The triple pole air break switch is gang operated and designed for outdoor application.

The triple pole air break switch is gang operated and designed for outdoor application.

The switch is intended for switching of the Transformer, Overhead lines, and Cables from the distribution system.

Types of AB Switch

Types of AB Switch

- Single Pole Air Break Switch

- The Gang Operated Air Break Switch

It can be operated manually using either a handle/ratchet mechanism or an insulated

‘hook stick’ made either of wood or fiberglass.

Air Break Switches are installed in either horizontal or vertical (Pole Top or Mid Pole) configurations.

Air break switches can be found either in substations or out on the distribution system

– either pole top or in pad-mounted metal enclosures.

Breakers, Reclosers, and Disconnectors

Circuit breakers can be designed using air, oil, vacuum, or SF6 gas as the dielectric.

Circuit breakers are only found in substations.

1. Recloser

A recloser is a lot like a circuit breaker both in function and also the choice of the dielectric.

Reclosers typically have less short circuit interrupting capacity than breakers,

but they are designed to automatically reclose to restore the interrupted circuit.

The reason for that is that most

(typically, more than 80% of the faults on overhead distribution circuits are self-clearing

(tree branches, small animals, etc) and can be restored if the circuit is allowed to remain de-energized for 10-15 seconds

so that the ionized air in the vicinity of the fault can dissipate. Reclosers are much less expensive than breakers.

2. Sectionalizer / Isolator

A sectionalizer/isolator is a device that is applied out on a distribution circuit that

is intended to determine that a fault is located downstream of the recloser.

The principle of operation is that once the sectionalizer/isolator makes the determination that the problem is downstream,

it can open, and then an upstream reclosing device (either a recloser or a circuit breaker)

can automatically reclose to restore service to those loads that are upstream of the sectionalizer.

A sectionalizer/isolator doesn’t have any current interrupting capability but instead

relies on the upstream device to interrupt fault current.

3. Disconnector

A disconnector is simply a device that is used to disconnect a load.

It can be an air break switch, or it could be a circuit breaker.

The name implies the function and is not necessarily descriptive of the device itself.

The term ‘isolator’ is a synonym for disconnector.

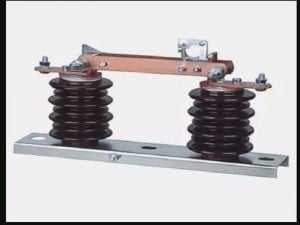

Knife Switch

a manually operated electric switching device that makes, breaks, or changes the course of electric circuits.

a manually operated electric switching device that makes, breaks, or changes the course of electric circuits.

The switch can operate either under load

, at voltages of up to 220 volts for direct current and 380 volts for alternating current, or in the absence of current.

The switch is characterized by the shape of its contact, which suggests a knife blade.

Depending on the number of contacts, knife switches are subdivided into single-pole, double-pole, triple-pole, and multipole types.

To increase the maximum current that can be interrupted, high-power knife switches are equipped with arc-quenching chambers.

When a single-pole knife switch is closed , the switch blade is turned about its axis by the handle and “cuts” into the stationary spring contact jaw.

When the load current is interrupted, an electric arc is established between the switch blade and the contact jaw,

and the arc is then extinguished in the arc-quenching chamber. The arc must be extinguished as soon as possible in order to avoid burning the contacts.

At currents below 75 amperes, the arc can be extinguished through a mechanical separation;

the time necessary to interrupt the arc depends on the speed at which the switch blade is moved.

In knife switches designed for higher currents,

the determining factors for extinguishing the arc are the arc’s electrodynamic rupturing forces.

The magnitude of these forces is directly proportional to the current being interrupted and approximately

inversely proportional to the length of the blade.

In order to make the speed at which the contacts are separated independent of the speed at which the handle is turned, a quick-break opening is effected with auxiliary contact blades.

Such an opening facilitates the extinguishing of the arc to a significant degree.

Knife switches are designed so that the contacts are not heated above permissible temperatures under

normal operating conditions and so that the contacts do not weld together during short circuits and do not open spontaneously.

Knife Switches

Knife Switches

What is a Knife Switch used for?

A knife switch is a form of switch- all or nothing- On and off,

and for this reason it is often used as a master switch or main-disconnect.

the single pole single throw has one switch blade, not the cutlery variety,

which vaguely resembles a knife, hence the name,

when the handle is down and touching the contacts the switch is closed and the power is on.

Lifting the handle disconnects the circuit. They are used for instructional purposes in shop and science classes.

A Double Pole, Double Throw knife switch- or circuit breaker,

is in everyday use and has defied obsolescence since the days of Edison.

The DPDT is used on master switches and controls two circuits, usually with a center off position.

They were used as aerial switches- to select transmit or receive in early shortwave and ham sets.

they are very much around and have been nicknamed (Mousetraps) from their shape and outline.

very much in use and I have a l907 electrical handbook that illustrates them some have shunts or condensers across the base

( wood or plastic, usually) of the switch. this has various uses but keeps the currents at a safe value in radio use.

Knife switches are becoming more rare,

finding use largely in science experiments where the position of the switch may be plainly seen in demonstration.

The knife switch is extremely simple in construction and use.

Abbreviations:

S = Single

D = Double

P = Pole

T = Throw

i.e: SPDT would be Single Pole, Double Throw

Here a knife switch is being used to turn

the motor on the paddle boat on/off.

Knife Switch, SPST

Product Code: SPST

Knife switch, single pole single throw, with screw type binding posts.

and 2 screw holes for mounting on a board. Good for experiments and science projects.

High quality, deluxe version.

Screw type binding posts may be both black or one black, one red.

Weight = 25g

Measurements:

Base Alone: Length = 74mm Width = 35mm Height = 10mm

Length with Pole = 98mm Height with Pole = 33mm

Knife Switch, SPDT

Product Code: SPDT

Knife switch, single pole double throw, with screw type binding posts.

and 2 screw holes for mounting on a board.

Good for experiments and science projects. High quality, Deluxe version.

Weight = 41.5g

Measurements:

Base Alone: Length = 74mm Width = 35mm Height = 10mm

Length with Pole = 105mm Height with Pole = 29mm

Knife Switch, DPST

Product Code: DPST

This Knife Switch is double pole, single throw with screw type binding posts.

3 screw holes for mounting on a board. Good for experiments and science projects.

High quality, Deluxe version.

Weight = 46g

Measurements:

Base Alone: Length = 74mm Width = 50mm Height= 10mm

Length with Pole = 100mm Height with Pole = 29mm

Knife Switch, DPDT

Product Code: DPDT

This Knife Switch is double pole, double throw with screw type binding posts.

3 screw holes for mounting on a board. Good for experiments and science projects.

High quality, Deluxe version.

Weight = 73g

Measurements:

Base Alone: Length = 74mm Width = 52mm Height = 10mm

Length with Pole = 106mm Height with Pole 29mm

Simple Switch (Knife Switch)

Simple Switch (Knife Switch)

Product Code: KSWITCH

This small size simple switch is used by students to make electrical circuits.

This quality knife switch is perfect for science projects and electronic experimentation.

With its pre-drilled holes, it can easily be mounted on any wooden surface or project board.

Because of the open structure of the switch, you can visually determine if the circuit is closed or open.

Weight = 9.3g

Measurements:

Base Alone: Length = 36mm Width = 24mm Height = 7mm

Length with Pole = 50mm Height with Pole = 23mm

electric fuse

We are pleased to have you visit our pages on social networking sites,

where we publish exclusive offers on our website.

Our Facebook page here .

Our Twitter account is here .

Leave a Reply

You must be logged in to post a comment.