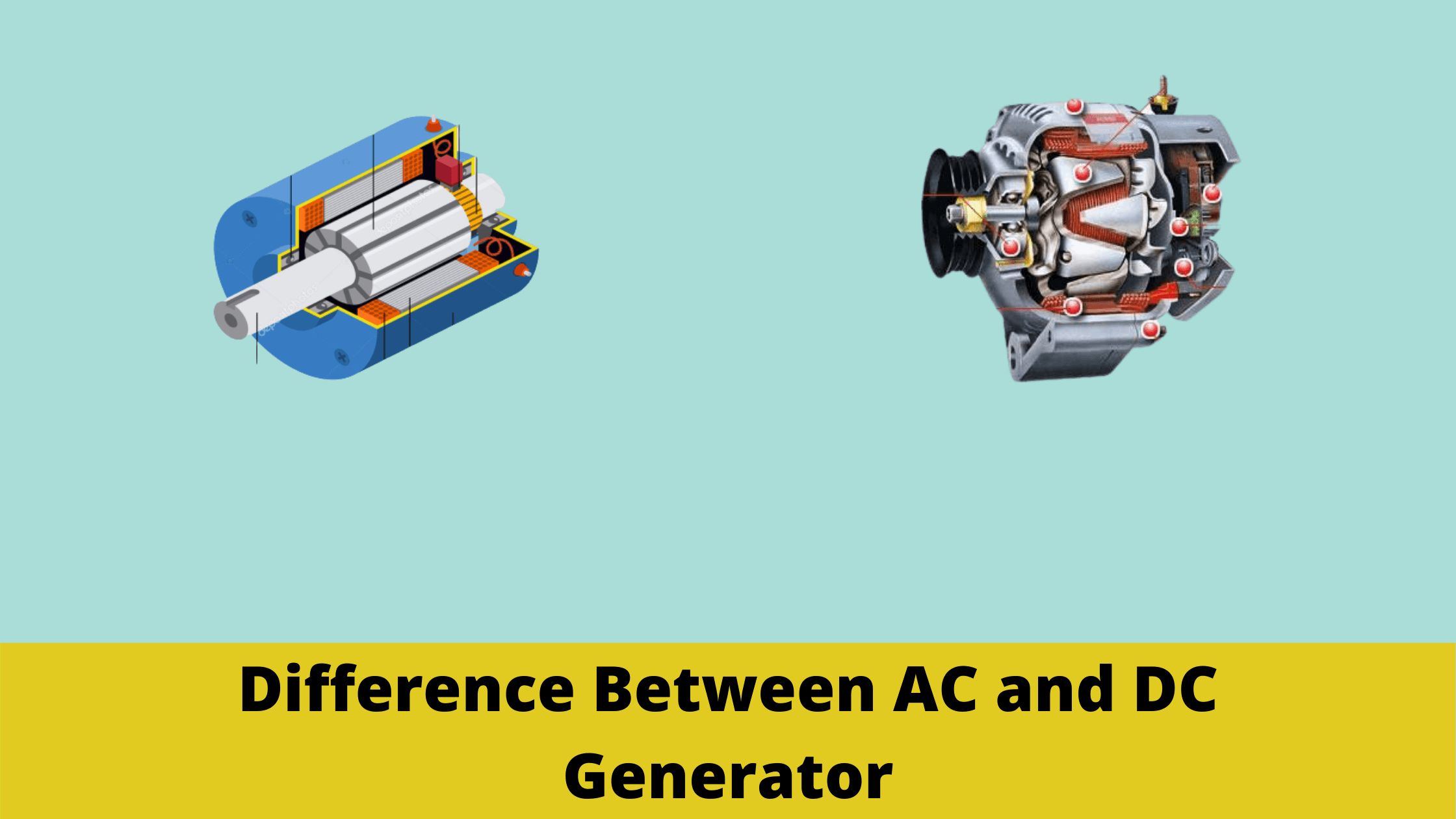

Difference between DC and AC generators 1

Difference between DC and AC generators: An easy to understand guide

There is a huge Difference between DC and AC generators although the names might seem the same to you. These two types of generators provide completely different outcomes. They both provide currents, but the final currents are different in terms of the way they move, their mechanism, their design, and their use. Here, Gahzly will explain the Difference between DC and AC generators and answer all the questions that may cross your mind while reading about the two. Let us first briefly introduce AC generators and DC generators.

An alternating current Generator produces an alternating current that reverses direction regularly. A DC generator, on the other hand, has a single-direction direct current. The coil through which current travels in an AC generator is normally stationary, whereas the magnet moves. DC and AC generators are important products for electrical systems. DC and AC generators are provided by several Suppliers And Companies, different manufacturers, and a lot of distributors and there are a lot of DC and AC generators For Sale on Gahzly.

There is a complete list of AC and DC generator services on the Gahzly website that covers all electrical demands. Gahzly vendors can assist you with this. Please contact Gahzly’s DC and AC generators Experts to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality items.

What is an AC generator?

AC generator is considered an electrical generator for converting mechanical energy into electrical energy. This energy is in the form of alternating current or alternative EMF. They work according to the principles of electromagnetic induction which states that electromotive force (EMF) is generated in a current-carrying conductor that cuts a uniform magnetic field. This can either be achieved by rotating a conducting coil in a static magnetic field, or by rotating the magnetic field that contains the stationary conductor. The preferred arrangement is to keep the coil stationary because it is easier to draw induced alternating current from a stationary armature coil than a rotating coil.

What is a DC generator?

DC generators convert mechanical energy into DC electricity which is short for Direct Current. DC generators work according to the principles of energetically induced electromotive force.

Now, let’s dig deeper into the Difference between DC and AC generators and learn about their use. Then, you’ll be able to decide which one suits your needs:

AC Generator vs Dc Generator

AC Generator vs Dc Generator

- The Design and Mechanism

- Use and Maintenance

- Connectivity

AC vs. DC: The Design and Mechanism

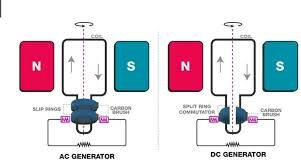

The Diff BW AC and DC Generator in terms of design is that the AC generators’ current moves through the fixed coil. The flow of current remains in the opposite direction, with the help of a moving magnet. While in DC generators the coil moves in a fixed field and the current flow with this movement, so no fixed coils for DC generators.

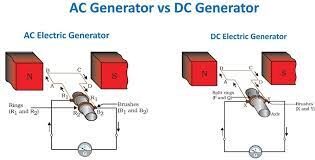

One of the similarities between DC and AC generators is that they both have slip rings (created from metal) and also an armature coil. The armature connects to the outside circuit with the help of a connection that directly affects the type of the produced current.

The AC generator has two metal rings that rotate with the armature coil simultaneously. Both ends of the armature are connected to a separate slip ring with a carbon brush to enable this process. But the AC generators contain a fixed brush. The brushes are the elements receiving the current flowing through the slip rings. However, both the end of the outside circuit and the end of the armature are connected to one brush.

Another Difference between DC and AC generators in this regard is that while AC generators have 2 slip rings, DC generators have only one. The two semi-circular metal rings in the commutator are insulated from one another. The ends of the armature in the DC generator are connected to one-half of the commutator. Then each half-turn rotation results in a reverse direction of the current in the armature.

The 180-degree rotation between magnetic poles by the armature then takes the current from its highest point to zero. The rings in an AC generator don’t have commutators while DC generators have Split-ring commutators. Plus, the smooth and uninterrupted surface of the AC slip-rings is highly efficient and does not wear quickly while both brushes of a DC generator are less efficient than AC generator since they wear out quickly. The efficiency of the brushes in the AC generator decreases the short circuit possibility but the possibility is high in DC generators.

Although both DC and AC generators have a different approach toward collecting and transferring induced electromotive forces in the external circuit, they both use electromagnetic principles to reach the desired outcome. So there’s another difference between AC generator and DC generator. This difference is due to the connection between armature and the external circuit in these two types of generators.

How AC and DC Are Generated?

DC may be produced in a variety of ways: Direct current can be generated by an AC generator with a device known as a “commutator.” The use of a “rectifier,” a device that converts AC to DC. Batteries produce DC as a result of a chemical process within the battery.

The Difference between DC and AC generators: Use and Maintenance

The output voltage produced by AC generators is called alternators. The normal frequency of alternators is 60Hz for America, Europe, and Japan. This output voltage differs in time and amplitude. DC generators produce a steady output voltage, suitable to power large motors. While DC generators are mainly used to supply power for large motors, AC generators are used for smaller ones. You can power your electrical appliances at home with the help of AC like food mixers, electrical fixtures, etc.

The Diff BW AC and DC Generator in terms of maintenance are huge. DC generators require constant maintenance and are less reliable while AC generators need very little maintenance and are more reliable.

AC vs. DC generator: Connectivity

Another Difference between DC and AC generators is their connectivity. DC generators have a design that provides seamless connectivity with efficient power flow. This is mostly because they don’t need any transfer switch. In the case of AC generators, however, they require much more effort to transfer electricity to remote sections of the grid, making it less efficient when it comes to connectivity.

Different types of DC and AC generators

AC generators

- Single Phase generator

- Synchronous generator

- Three Phase generator

- Induction generator

DC generators

- Self-excited DC generator

Series wound generator

Shunt-wound generator

Compound wound generator

- Separately-excited DC generator

DC and AC generators have different types for different uses and needs. Some of them are as follows:

AC generators have different types such as Single Phase generators, Synchronous generator, three Phase generators, Induction generator, etc.

- Single Phase generators: Single-phase generator (also known as a single-phase alternator) is an alternating current electrical generator that produces a single, continuously alternating voltage. Single-phase generators can be used to generate power in single-phase electric power systems.

- Synchronous generators: The synchronous generator or alternator is an electrical machine that converts the mechanical power from a prime mover into an AC electrical power at a particular voltage and frequency. The synchronous motor always runs at a constant speed called synchronous speed.

- Three-phase generators: Three-phase generators work by producing three separate waves of AC power that operate in a sequence, ensuring that there is always a continuous flow of energy and that the power level never dips as it does with single-phase generators.

- Induction generators: An induction generator is also known as an asynchronous generator that has a working principle similar to that of an AC generator. The only difference between a normal AC generator and an induction generator is that the induction generator is a rotating device. It is known as asynchronous because the speed of the induction generator is less than that of the synchronous generator. They find applications in mixers and grinders.

DC generators mainly have two types: Self-excited DC generator and Separately-excited DC generator. Their armature connection is the same and that’s why they are categorized as DC generators.

- Self Excited: In a self-excited type, the field coils are energized from the generated current within the generator. These types of generators can further be classified into Series wound generators, Shunt wound generators, and compound wound generators.Series wound: field winding in series with the armature winding

Shunt-wound: field winding in parallel with the armature winding

Compound wound: the combination of series and shunt winding - Separately Excited: In a separately excited type generator, the field coils are energized from an independent exterior DC source.

Which one is better: AC generator or DC generator?

Finding the best one between AC generator vs Dc generator largely depends on the way you want to use it and your desired outcome. Each of them has several advantages enabling you to get the most out of them, such as:

DC Generators advantages

- Smooth Voltage

- Suitability for large motors

- Simple design

AC Generators advantages

- Suitability for electrical appliances and small motors

- Low maintenance needs

- Easy distribution of the output with a transformer

- Efficiency

- Losses are relatively fewer than DC Generators

- Transmission link size might be thinner because of the step-up feature

- AC generators can be easily stepped up and stepped down through transformers.

- The size of the AC generators is relatively smaller than DC generators.

It’s also good to know that DC generators are more affordable compared to AC generators. AC generators cost a little more.

So, now you know everything you needed to know about the difference between these two! Do you think the difference between AC and DC generator affects other aspects of your life or the industry other than what we mentioned above? Share your thoughts with us in the comment section. And feel free to sign up on our website if you want our experts to answer your most complicated questions regarding this field.

What is the Working Principle of DC Generator?

Generators are electrical machines whose job gets started when the electrical power from the local grid goes off. Here is where the generators start to work to provide the electricity. These electrical machines work as a source to supply electrical power for many business facilities, industrial buildings, and even homes when the electrical power has cut off. Generators are categorized into two types of AC and DC generators. We are here to explain the question “what is the working principle of DC generator?” and discuss DCs in detail. Gahzly has gathered the most to-the-point and precise pieces of information on this topic for you to read.

Before we discuss the main topic of this article, we have to know about the structure and the main functions of DCs. Let’s have a brief look at DC generators’ construction, functions, and part and components.

On Gahzly’s platform, you will find all the information you need regarding DC generator equipment and devices. Gahzly’s experts are available to help with any questions you might have about DC Generators. Take a moment to read “What Is DC Generator?“.

What Is a DC generator?

As mentioned before, there are two types of generators based on the output: AC and DC generators. Direct current generators’ main function is to change mechanical energy into electricity. There are a lot of sources that provide mechanical energy for DC generators such as engines with internal combustion, water, gas, and steam turbines, and even hand cranks. There is a reverse function defined for DC generators: this reverse job can be accomplished by the use of an electrical motor.

DC motor changes the electrical power into mechanical energy. DC generators produce electrical power based on the principle of faraday’s law of electromagnetic induction. Based on this law, when a conductor moves in a magnetic field, the magnetic lines of force are cut. This leads to an electromagnetic force induction in the conductor.

To have a clearer answer to the question “what is the working principle of DC generator?”, let’s have a brief elaboration on its parts and components as well. In the following section, we will tell you very briefly about the main parts of a DC generator and how they work. keep reading.

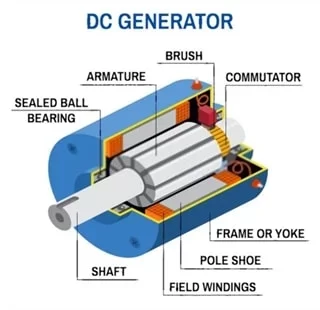

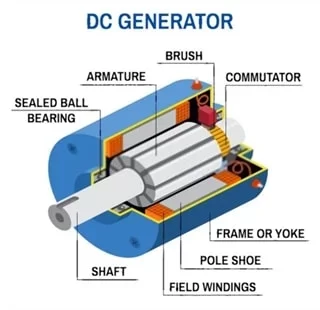

Construction of a DC generator

In the previous section, we explain what a DC generator is very briefly. Now we want you to be more familiar with its construction. There are many components in a single DC generator which help the whole machine to function as the way it should do. In various articles, more than ten parts are mentioned for DC generators.

We are not going to elaborate on all of these components because the explanation of the function of these parts is beyond the scope of this article and will take us away from the main topic of our discussion. In the following sections, you will read about four of the most important components of a DC generator helping you to carve the answer to the question “what is the working principle of DC generator?”

Stator

Stator

one of the most essential parts of a DC generator is the stator whose job is to supply magnetic fields around which the coils spin. The stator consists of two stable magnets with opposite poles facing each other. These magnets are put to fit in the region of the rotor.

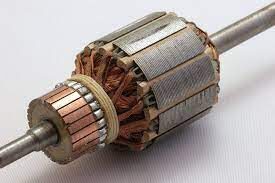

Rotor

The rotor or the armature core is another important part of a DC generator. There are slotted iron laminations in the rotor with slots that have been stacked to form a cylindrical armature core. Generally, the losses are decreased due to the eddy current in these laminations.

Commutator

The operation of the commutator is like a rectifier to convert AC voltage to DC voltage in the reinforcement of the armature winding. It has a copper segment and each copper segment with the aid of mica sheets is shielded from each other. It sits on the machine’s shaft.

Brushes

With the aid of brushes, the electrical connection between the commutator and the external load circuit can be assured.

Now that you are familiar with the essence and the main components of a DC generator, it is like a piece of cake to understand how a DC generator works. In the following section, we are going to discuss how a DC generator operates in a comprehensible language. Stay with us.

What Is the Working Principle of DC Generator?

In previous sections, we discussed what defines a DC generator and how it works. In this section, we are about to talk about DC generators’ working principle.

As mentioned before, a DC generator is an energy converter that turns mechanical energy into electrical. This change in the form of energy happens based on the principle of electromagnetic induction which means wherever a change in the magnetic flux happens associated with a conductor, an EMF or an electromagnetic force is induced in it. This induction causes a current to flow in case the conductor circuit is closed.

So, based on what we have said so far, the main requirements of a DC generator are the magnetic field and a conductor. The conductor moves to cut the magnetic flux. Therefore, we can say that a DC generator operates on the principle of the dynamically induced electromagnetic force. It is what Faraday’s law of electromagnetic induction says: when a current-carrying conductor is put inside a varying magnetic field, an EMF is induced in the conductor. On the other hand, and based on Fleming’s right-hand rule, wherever the direction of the motion of the conductor changes, the direction of the induced flow changes too.

Imagine an armature rotating clockwise and a conductor at the left moving upwards. Now when the armature accomplishes a half rotation, the direction of the movement of the conductor will be reversed downward. So, the direction of the current in every armature will be changing. But with a split ring commutator, connections of the armature conductors get reversed when a current reversal occurs. Therefore, we get unidirectional current at the terminals.

An Easy-to-understand Example of DC Generator Working Principle

Let us make the DC generator’s function and working principle simpler for you. You have to notice if the generator is very small for example it is used for a shop, a small workshop, a cinema, or a house, the prime mover or the mechanical energy supplier is a diesel engine. If the generator is very big like in power plants, then the prime mover will be a water, steam, or gas turbine.

As the mechanical energy supplied by the prime mover is given to the generator, the generator armature starts rotating. Usually, the poles on the yoke are made of permanent magnets. It means that according to Faraday Laws of Electromagnetic Induction, the armature conductors cut the weak magnetic field established by permanent magnets and a small amount of EMF is induced in the armature winding. This induced electromagnetic force circulates a small amount of current through the field winding and strengthens the magnetic flux supplied and hence the induced EMF. Thus, due to the reinforcement of the flux and EMF, the generator provides the rated voltage.

What Are the Applications of DC generators?

Portable DC generators are used where a low power supply is needed. Besides being used as dynamos for motorcycles, they can also be found in toys, such as remote control cars, and household appliances, such as electric shavers. For arc welding, which requires massive voltage drops and constant current, generators of this type are used.

What Are the Types of DC Generators?

The following are the three main types of DC generators based on excitation methods:

- Permanent Magnet DC Generators in which field coils are excited by permanent magnets.

- Separately Excited DC Generators which have field coils excited by an external source.

What Are the Advantages of DC Generators?

Most DC generators are highly reliable, rated at 85-95% efficiency. They are compact and lightweight. DC generators produce constant and consistent output. They can also be modified to provide different outputs.

Conclusion

What is the working principle of DC generator was the main topic of this article which we tried to answer. To answer this question, firstly, we decided to have a very short but useful explanation of what a DC generator is. The next step was to get acquainted with the main components of this energy convertor. So, we elaborated on 4 of the most important parts of a DC generator and how they work.

finally, we got into the section of what the working principle of a DC generator is and we tried to explain it with a vivid example. If you any other questions about the topic, Gahzly is ready to answer them. All you need is to sign up. Besides, if you have any experience of using DC generators, we will be glad that you share it with us in the comments. Hope you enjoyed this article.

Working Principle of AC Generator

Working Principle of AC Generator

Working Principle of AC Generator – An alternating current generator (AC generator) is a device that converts mechanical energy into alternating electrical energy for use. AC generators employ slip rings to produce alternating current, whereas DC generators use direct current. Power plants, sailboats, electric scooters, bicycles, and other applications all employ AC generators. Mechanical energy is typically supplied to AC generators by steam and gas turbines, as well as internal combustion engines. AC generators are useful in wind turbines, small hydropower plants, and converting high-pressure gas streams to lower-pressure gas streams.

The Gahzly platform offers you all the information you need about AC generator equipment, devices, and related products that are available in the market today. .

What is an AC Generator?

What is an AC Generator?

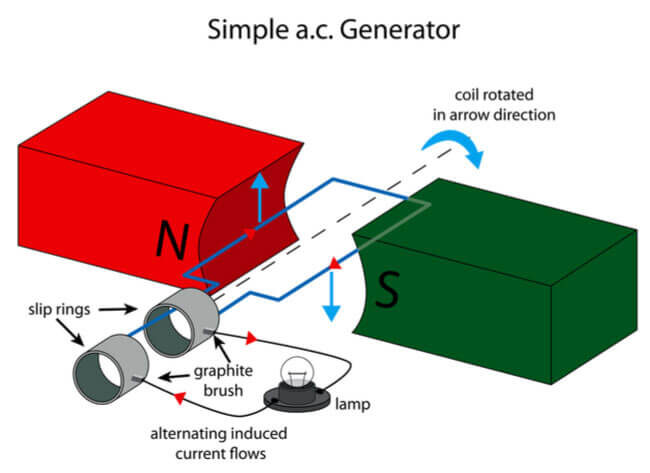

A machine that turns mechanical energy into electrical energy in the form of alternate EMF is known as an AC generator. Faraday’s Law of Electromagnetic Induction governs the operation of a simple AC generator. It’s made out of a wire coil that spins in a magnetic field.

Working Principle of AC Generator

The Working Principle of AC Generators is that they are frequently referred to as alternators and operate on the principle of Faraday’s Law of Electromagnetic Induction. The magnetic flux associated with the coil changes when a conductor moves in a uniform magnetic field, causing an EMF.

Electricity is widespread, from flipping a switch to heating a snack in the microwave. You might be wondering how this vital energy source is generated and delivered to your home now that you’ve given it some attention.

Turbines and generators are used to generate electricity in power plants. Electric generators convert rotation into electricity, while turbines transform available energy into rotation. Generators are divided into two groups based on their electric output: AC Generators and DC Generators. The functioning principle and components of an AC generator will be discussed in-depth in this post. If you want to learn more about the working principle and characteristics of a DC generator, visit our post DC Generator.

A machine that converts mechanical energy into electrical energy is known as an AC generator. Mechanical energy is supplied to the AC Generator through steam turbines, gas turbines, and combustion engines. Alternating electrical power in the form of alternating voltage and current is the output.

Faraday’s law of electromagnetic induction states that electromotive force (EMF or voltage) is generated in a current-carrying conductor that cuts a uniform magnetic field. AC generators work on this basis. Rotating a conducting coil in a static magnetic field or rotating the magnetic field enclosing the stationary conductor can both be used to accomplish this. Because it is easier to extract induced alternating current from a stationary armature coil than from a revolving coil, this is the favored configuration.

The coil, slip rings, brushes, and a strong magnetic field are the main components of the AC generator.

The Function of AC Generator in Details

To create a strong magnetic field, the coil is rotated in the magnetic field. An EMF is induced in one direction as a coil goes up through the magnetic field on one side. An EMF is induced in the reverse direction as the coil rotates and this side of the coil moves down and another side of the coil moves up. The direction of the induced EMF is determined using Fleming’s right-hand rule. Every cycle, this process is repeated, and the EMF generated is of the alternating type.

A graph depicting the output of an AC generator is displayed above. The description of the letters are as follows:

- A – When the coil is at 0 degree, it moves parallel to the magnetic field’s direction and so produces no EMF.

- B – The coil moves at 90 degrees to the magnetic field and hence induces the most EMF when it is at 90 degrees.

- C – When the coil is rotated 180 degrees, it moves parallel to the magnetic field again, causing no EMF to be generated.

- D – When the coil is at 270 degrees, it goes back to 90 degrees to the magnetic field, inducing the maximum EMF. The induced EMF in this case is the polar opposite of B’s.

- A – The coil has completed one rotation when it reaches 360 degrees when it moves parallel to the magnetic field and produces zero EMF.

Consider a rectangular coil with ‘N’ turns rotating in a homogeneous magnetic field ‘B’ with an angular velocity of ‘’. At every time ‘t’, the angle between the magnetic field ‘B’ and the normal to the coil is given by, θ = ωt.

The magnetic flux is perpendicular to the plane of a coil in this location, and it is given by B Cos ωt. The magnetic flux associated with a coil of N turns is equal to ɸ = B Cos ωt A, where A is the coil’s area. Faraday’s Laws of Electromagnetic Induction determine the induced EMF in the coil.

�=−����=−�(��������)��=�������(��)

When the coil rotates through 90 degrees, the value of sine approaches 1 and the induced EMF reaches its maximum, reducing the preceding equation to:

�0=�����=����2��

Where

The maximal flux density in Wb/m2 is denoted by Bm,

The area of a coil in m2 is denoted by the letter ‘A’,

And ‘f’ stands for the frequency of a coil’s rotation in revolutions per second.

By Substituting the second equation in the first one,

�=�0���(��)

The term “induced alternating current” refers to the current that is generated when a device is turned on.

�=��=�0������

The flux linkage of the armature varies continually as it revolves between the poles of the magnet on an axis perpendicular to the magnetic field. An electric current travels through the galvanometer, slip rings and brushes as a result. The galvanometer changes its value from positive to negative. This implies that the galvanometer is receiving an alternating current. Fleming’s Right-Hand Rule can be used to determine the direction of the induced current.

Construction of AC Generator Principle

The Rotor and Stator are the two major components of a simple AC generator. A rotor is a revolving component, whereas a stator is a machine’s fixed component.

Stator

The stator is a stationary component that holds the armature coil in place. The objective of the armature winding is to carry current to the load, which might be any external equipment that uses electricity. It is divided into three sections:

- Stator Frame – It’s an exterior frame that holds both the stator core and the armature windings.

- Stator Core – To reduce eddy current losses, it is laminated with steel or iron. To hold armature windings, slots are cut into the interior of a core.

- Armature Windings – Armature windings are wound on armature core slots.

Rotor

An AC generator’s rotor is a rotating component. Magnetic field windings make up the structure. Magnetic poles are magnetized using a DC source. Slip rings are attached to each end of the magnetic field windings. The rotor rotates on a common shaft, which is coupled to this combination. Salient pole rotors and cylindrical pole rotors are the two types of rotors.

Salient Pole Rotor

The most important pole rotor type is depicted in the diagram below. The number of poles protruding, known as salient poles, with their bases fixed to the rotor, may be seen in this sort of rotor. They’re used in applications with low and medium speeds.

Cylindrical Pole Rotor

Cylindrical rotors have an unruffled and sturdy cylinder with slots positioned on the cylinder’s outside surface. It’s employed in applications that require a lot of speed. The cylindrical pole rotor is seen in the diagram below.

Types of AC Generator Principle

Types of AC Generator Principle

AC generators are classified into two types based on their working principle.

Asynchronous Generators

Induction generators are another name for asynchronous generators. Slip aids the rotor’s rotation in this type of generator. The rotor tries but fails to match the stator’s synchronous speed. When the rotor equals the stator’s synchronous speed, the relative velocity is zero, and the rotor has no torque. They can be used to power wind turbines.

Synchronous Generators

A synchronous generator is an AC generator that rotates at the same speed all the time. It works on the basis of Faraday’s law of electromagnetic induction, which states that when a coil rotates in a uniform magnetic field, an EMF is induced. They are mostly utilized to create high voltages in power plants.

Applications

The AC generator is used to generate electricity from windmills, hydroelectric dams, and other sources.

Advantages of AC Generators over DC Generators

AC generators have the following advantages over DC generators:

- Through transformers, AC generators can be simply stepped up and down.

- Because of the step-up feature, the transmission link size in AC Generators is less.

- The losses in AC generators are lower than those in DC machines.

- An AC generator is smaller in size than a DC generator.

The majority of us begin our studies with direct current, but we soon discover that it is not the only sort of current we encounter. Voltages and currents that are alternating in nature are produced by some power sources. Alternating current, or AC, is the name for this type of electricity. The video will assist you in understanding the Working Principle of the AC Generator.

FAQs about the Working Principle of AC Generator

1) What Is the Difference Between the AC Generator and the DC Generator?

The electrical current in an AC generator alternates its direction regularly, resulting in alternating current. The electrical current in a DC generator flows in only one direction.

2) Do Car Alternators Have AC or DC?

The rotating armature generates the AC, which is converted to DC using a commutator and brushes.

3) AC Generator Works on Which Principle?

It operates according to Faraday’s Laws of Electromagnetic Induction.

4) What Are the Types of AC Generators?

Synchronous and Asynchronous AC generators.

5) Are Batteries AC or DC?

Batteries are classified as DC because they only conduct current in one direction.

6) How Does an AC Generator Produce Electricity?

Faraday’s law of electromagnetic induction governs the operation of AC generators. The flux linkage of the armature varies continually as it revolves between the magnet’s poles on an axis perpendicular to the magnetic field. An EMF is created in the armature as a result of this. An electric current travels through the galvanometer, slip rings and brushes as a result.

7) What Factors Do the Generated EMF In an Alternator Depend Upon?

The amount of EMF created is determined by the number of armature coil turns, magnetic field intensity, and rotational field speed.

8) What Are Some Advantages of AC Generators Over DC Generators?

Through transformers, AC generators can be simply stepped up and down. The losses in AC generators are lower than those in DC machines.

9) In which part of the AC generator is the output generated?

The armature is where the output is generated.

The AC generator and its operation were explored in this post.

electric fuse

We are pleased to have you visit our pages on social networking sites,

where we publish exclusive offers on our website.

Our Facebook page here .

Our Twitter account is here .

Leave a Reply

You must be logged in to post a comment.