Scame Cable Galand IP66

Price range: 28,22 EGP through 166,82 EGP

- Gland Cable Scam IP66

- Manufacturer: SCAME

- Product type: cable plugs and valves

- Colour: light grey

- Material: plastic (polyamide)

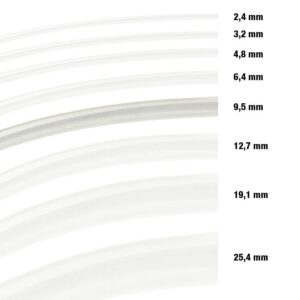

- (11 mm) – (13.5 mm) – (16 mm) – (21 mm) – (29 mm) – (36 mm) – (42 mm) – (48 mm).

- Easy to handle, no need to disassemble.

- Protection level: IP66 highly waterproof

- Technopolymer cable gland with jaw protection, with nut.

- Thread length 12mm, hitch hole 24mm

- Used for cables with a diameter of 7 – 12 mm

- Working temperature: -40 to 100

- Applied to cable fixing, waterproof design and so on.

- Age: long life