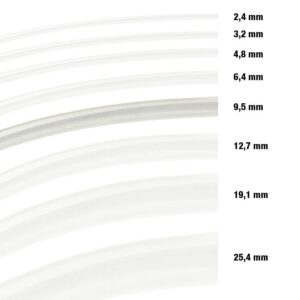

Fiberglass Cable Elcab Tinned Copper White

Price range: 2.343,00 EGP through 19.910,00 EGP

-

Fiberglass Cable Elcab Tinned Copper White

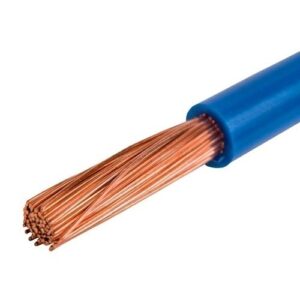

- Product or component type: power cord

- Colors: white

- Material: plastic

- AC at 50 / 60 Hz

- IP protection grade: IP20

- Age: long life