End Wire Cap

- Manufacturer: BBE

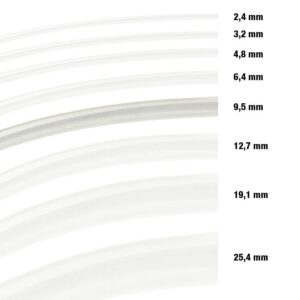

- Type: Wire Protection Cap

- Colors: Yellow – Red

- Materials: Heat-Resistant Insulating Materials

- Terminal Body: Copper

- Maximum Temperature: 75°C

- Ideal For: Most general-purpose applications

- Durability: Long-lasting

190,00 EGP – 590,00 EGPPrice range: 190,00 EGP through 590,00 EGPEarn up to 590 points.

190,00 EGP – 590,00 EGPPrice range: 190,00 EGP through 590,00 EGPEarn up to 590 points.

End Wire Cap

Safe and fast payment methods

Free 100%

Warrant exchange

Prices for Elsewedy cables and wires 2024 Prices for Elsewedy cables and wires 2024 Prices of Elsewedy cables and wires 2024, the companies...

Read More

قصة اختراع القاطع الكهربائي: من توماس أديسون إلى ذكاء 2026 اكتشفي تاريخ اختراع القاطع الكهربائي وكيف تطور من مجرد "فيوز" بسيط...

Read More

دليل 2026 لـ تأسيس المطبخ الذكي: توزيع الأحمال والحلول المخفية تعلمي أسرار تأسيس المطبخ الذكي لعام 2026. من توزيع الأحمال...

Read More

الذكاء الاصطناعي في الكهرباء: لوحات توزيع تتوقع الأعطال 2026. اكتشف كيف يغير الذكاء الاصطناعي في الكهرباء منزلك. تعرف على...

Read More

مستقبل إنترنت الأشياء (IoT) في الكهرباء: تحكم في منزلك من أي مكان 2026. اكتشف سحر إنترنت الأشياء (IoT) في الكهرباء....

Read More

هل منزلك جاهز؟ كيفية تأسيس نقطة شحن لسيارتك الكهربائية في الجراج 2026. هل اشتريت سيارة كهربائية؟ تعلم خطوات تأسيس نقطة شحن...

Read More

دليل القواطع المغناطيسية: كيف تعمل وأهميتها في حماية الأجهزة 2026. اكتشف كل ما يخص القواطع المغناطيسية. تعرف على ميكانيكية عملها،...

Read More

ممارسات صيانة قواطع دوائر الهواء: ضمان طول العمر والأداء. اكتشف الدليل الشامل حول صيانة قواطع دوائر الهواء (ACB). تعلم كيفية الحفاظ...

Read More

دليل العناصر الإلكترونية النشطة: أنواعها وكيفية عملها 2026 تعرف على أهم العناصر الإلكترونية النشطة من الديود والترانزستور إلى الدارات المتكاملة. دليل...

Read More

ما الذي يجعل الألواح الشمسية قابلة للاشتعال؟ أسباب وحلول أمان 2026 هل تتساءل ما الذي يجعل الألواح الشمسية قابلة للاشتعال؟ اكتشف...

Read More

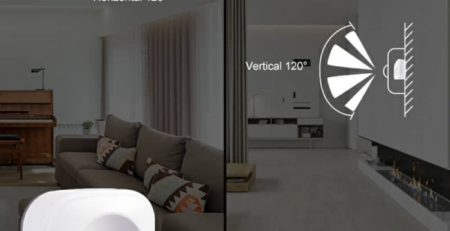

مستشعرات الحركة (Motion Sensors): كيف توفر الكهرباء وتؤمن منزلك؟ اكتشف كيف تعمل مستشعرات الحركة على توفير الكهرباء وحماية منزلك. دليل "جهزلي"...

Read MoreEthically sourced, small-batch roasted—experience bold dark roasts to smooth medium blends. Discover your perfect cup.